Highly Accurate Pressure Sensors - Industrial Safety Standards

2023-09-27 16:58In the modern industrial sector, safety has always been a crucial aspect, and the high-precision pressure sensors are undoubtedly one of the key players in maintaining industrial safety standards. In this article, we will take an in-depth look at the role of high-precision pressure sensors in industrial safety and how they support the principle of "zero tolerance for compromise".

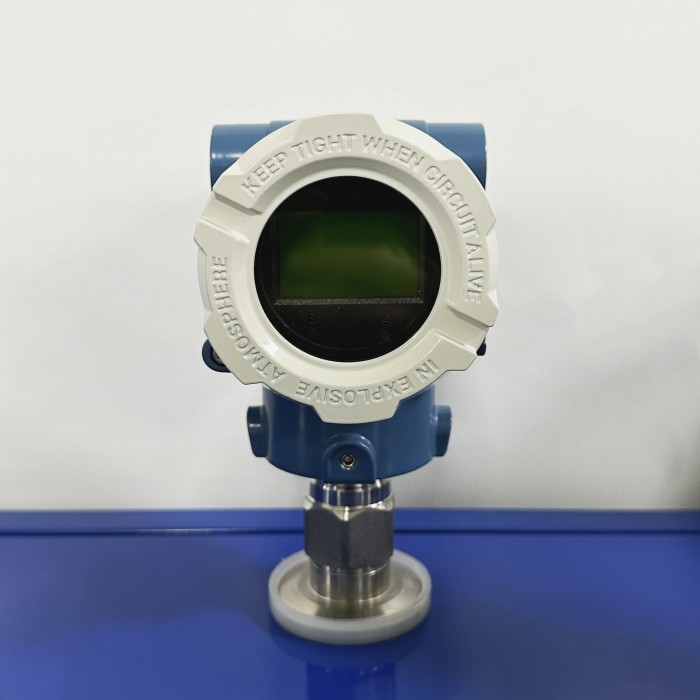

There are a variety of pressure changes in industrial production environments that may cause potential hazards. By monitoring and measuring gas or liquid pressure in real-time, high-precision dp pressure sensor can detect abnormalities in time to take the necessary measures to prevent accidents. The following are the main functions and application areas of smart pressure transmitters:

1. Industrial pressure transmitters are used to measure pressure in liquids or gases. These measurements can be used to monitor and control various industrial processes, including level measurement, flow measurement, pressure control, and more.

2. In industrial automation systems, digital pressure transmitters are used to monitor pressure changes in piping, vessels, or equipment to ensure that the industrial activities operate within safe limits. If the pressure exceeds the specified range, the system can take appropriate measures, such as closing valves or issuing alarms, to prevent accidents.

3. In some applications, such as petrochemical, nuclear, and aircraft manufacturing, ATEX pressure transmitters are used to monitor pressure in critical components to ensure safe operation. Any change in pressure beyond the permissible range can lead to equipment failure or accidents, so timely monitoring is essential.

4. Vacuum pressure transmitters are often integrated with data acquisition systems to record and store pressure data. This data can be used for analysis, reporting, and maintenance purposes, helping to improve system reliability and efficiency.

The principle of "Zero Tolerance for Compromise" emphasizes a high degree of vigilance on safety issues. The accuracy and stability of high-precision pressure transmitter HART enable personnel to respond quickly and take action to prevent possible accidents. This precision not only protects the live-safe but also helps to minimize production interruptions and losses.

By collecting and analyzing large amounts of pressure data, engineers and managers can better understand pressure trends and patterns of change in the work environment. Such a data-driven approach makes predicting potential problems much more accurate, allowing preventative measures to be taken before accidents occur.

In short, high-precision pressure transmitter sensors play an integral role in ensuring industrial safety standards. By monitoring and accurately measuring pressure in real-time, they effectively support the principle of "zero tolerance for compromise", creating a safer production environment for workers.