Water Steam Application Vortex Flow Meter

- Information

- Product Description

- Video

- Download

Product Introduction

Vortex flowmeter is a cutting-edge flow measuring device developed on the basis of vortex principle. The innovative technology has reached the international advanced level and is the first choice of various industries. Vortex flowmeters have unique advantages. vortex water flow meter provides high precision, extensive measurement capabilities and minimal maintenance requirements. This makes vortex flow sensor highly reliable in a variety of applications. These meters are suitable for measuring mass flow and volume flow in various media. According to different media, this can be divided into steam vortex flowmeter, vortex water flowmeter and other products. Vortex flowmeters work by detecting the frequency of vortices flowing out of a blunt body placed in an air stream. As fluid flows through the body, it creates alternating low-pressure vortices proportional to the flow rate. The principle allows for precise measurements under a wide range of conditions, ensuring accurate and consistent readings. With its powerful design and versatility, vortex flow meters are widely used in energy, water treatment, chemical processing and HVAC systems to help improve the efficiency and performance of fluid management.

Product Features

Robust and compact design: steam vortex flow meters have a simple and robust construction that ensures durability and ease of installation.

Easy maintenance: No pulse piping or three-valve manifolds are required, and the steam vortex flow meter's design simplifies maintenance by minimizing the risk of leaks, clogging and freezing.

Reliable performance: Measuring components for vortex steam flow meter's design reliability contributes to long service life and consistent performance over time.

High measurement accuracy: Vortex flow sensor's offer impressive accuracy. Readings are usually stable at ± (1 to 1.5) %.

Simultaneous display: The device displays both traffic and cumulative traffic values without switching between displays.

Optimized construction: The vortex flow meter for steam application promotes a wide dynamic measurement range while maintaining low pressure losses, increasing efficiency in a variety of applications.

Product Parameters

Nominal diameter (mm) | 25,40,50,65,80,100,125,150,200,250,300,(300~1000 Insert type) |

Nominal pressure (MPa) | DN25-DN200 4.0(>4.0 Supply agreement),DN250-DN300 1.6(>1.6 Supply agreement) |

Medium temperature(°C) |

Piezoelectric type:-40~260,-40~320;Capacitance type : -40~300, -40~400,-40~450(Supply agreement)

|

Body material

| 1Cr18Ni9Ti,(Other materials supply agreement) |

Allowable vibration acceleration

| Piezoelectric type:0.2g Capacitance type:1.0~2.0g |

Accuracy

| ±1%R,±1.5%R,±1FS;Insert type:±2.5%R,±2.5%FS |

Range of

| 1:6~1:30 |

Power supply voltage |

Sensor:+12V DC,+24V DC;Transmitter:+12V DC ,+24V DC;Battery type:3.6V Battery

|

Output signal

| Square wave pulse ( not including the battery power supply type ): high level or low level5V,1V; current: 4~ 20mA |

Pressure loss coefficient

| In line with the JB / T9249standard Cd = 2.4 |

Explosion proof marks

| Intrinsic safety type: Exd IA CT2-T5 flameproof type: Exd CT2-T5 |

Protection grade

| The ordinary IP65 diving type IP68 |

Environmental conditions

| Temperature - 20~ 55,5% ~ 90% of relative humidity, atmospheric pressure is 86 ~ 106kPa |

Applicable medium

| Gas, liquid, steam |

Transmission distance

| Three wire system pulse output type: < 300m, two line standard current output type (4 ~ 20mA ): load resistance less than 750ohm |

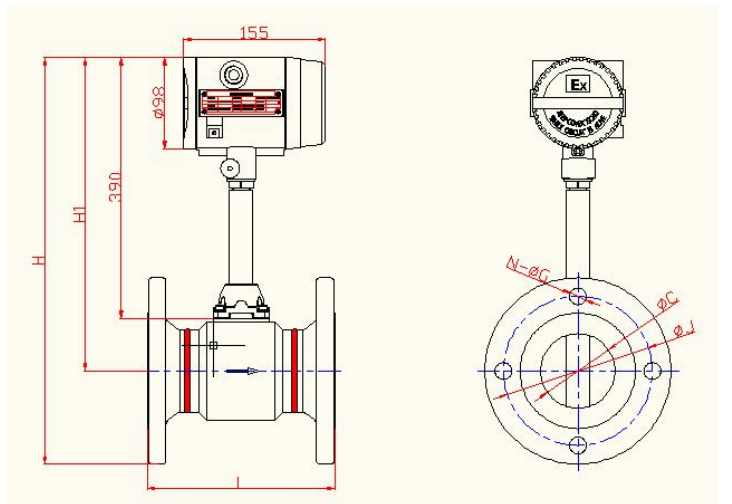

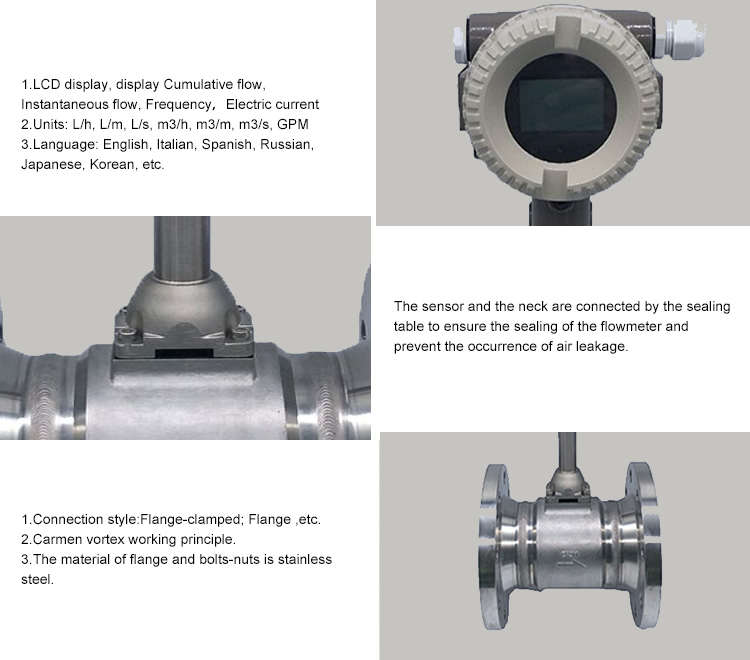

Product Detailed Images

Product order sheet

LUGB | Explanation | ||

Nominal diameter (In mm) | diameter | DN15-300(Pipeline) | |

DN200-1500(Plug-in) | |||

Connection | Pipeline | FL | Flange connection |

JZ | Flange clamp | ||

Z | Special rules | ||

Insert | J | Simple Formula | |

Q | Ball type | ||

Accuracy | Pipe line | 10 | 1.0%R |

15 | 1.5%R | ||

Insert | 20 | 2.0%R | |

25 | 2.5%R | ||

Z | Special accuracy standards | ||

Temperature and pressure | S | T(S)P(S)At normal temperature and pressure | |

Z | T(Z)P(Z)Twin extreme pressure | ||

Communication protocol | N | No communication interface | |

H | HART protocol | ||

M | MODBUS protocol | ||

Output | 1 | No output | |

2 | Two-wire 4-20mA output | ||

3 | Pulse output | ||

D | DC12V | ||

Power supply | DB | Dual 12V power supply and battery | |

DD | DC24V | ||

B | Battery 3.6V power supply, no signal output uses only | ||

Sensor Material | S | 304Stainless steel | |

L | 316Stainless stee | ||

Core Component Materials | S | 304Stainless steel Probes | |

L | 316Stainless steel Probes | ||

Measuring medium | 1 | Gas | |

2 | Liquid | ||

3 | Saturated steam | ||

4 | Superheated steam | ||

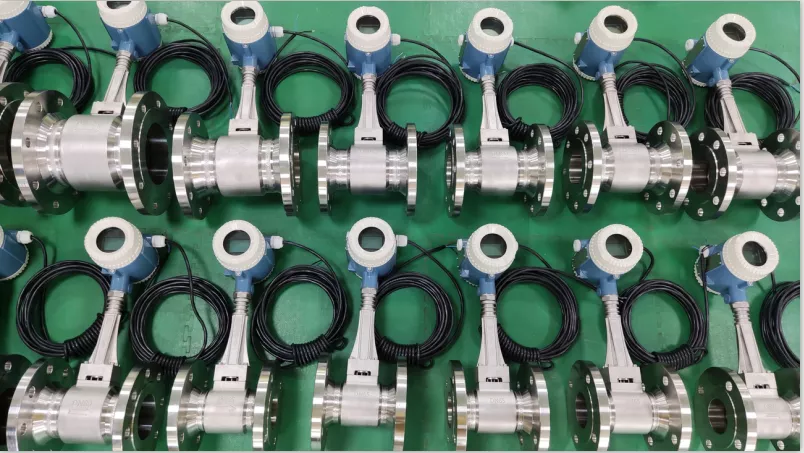

Production Line

2. The steam vortex flow meter is not in contact with the medium, with stable quality and strong durability. The vortex flow sensor is usually installed separately from the eddy current, and the high-temperature piezoelectric effect seal does not contact the measured medium in the detection probe. Therefore, the vortex steam flow meter has the characteristics of simple structure, good general performance and high stability.

3. The vortex flow sensor is widely used, can be used for steam, gas and water.2. Non-Contact Measurement for Stability and Durability: The steam vortex flow meter operates without direct contact with the medium, ensuring stable quality and robust durability. The vortex flow sensor is typically installed separately from the eddy current component, with a high-temperature piezoelectric seal that prevents contact with the measured medium in the detection probe. This design imparts characteristics such as a simple structure, reliable performance, and high stability to the steam vortex flow meter.

3. Wide Range of Applications: The vortex flow sensor is versatile and suitable for measuring steam, gases, and water, making it applicable across various industries.