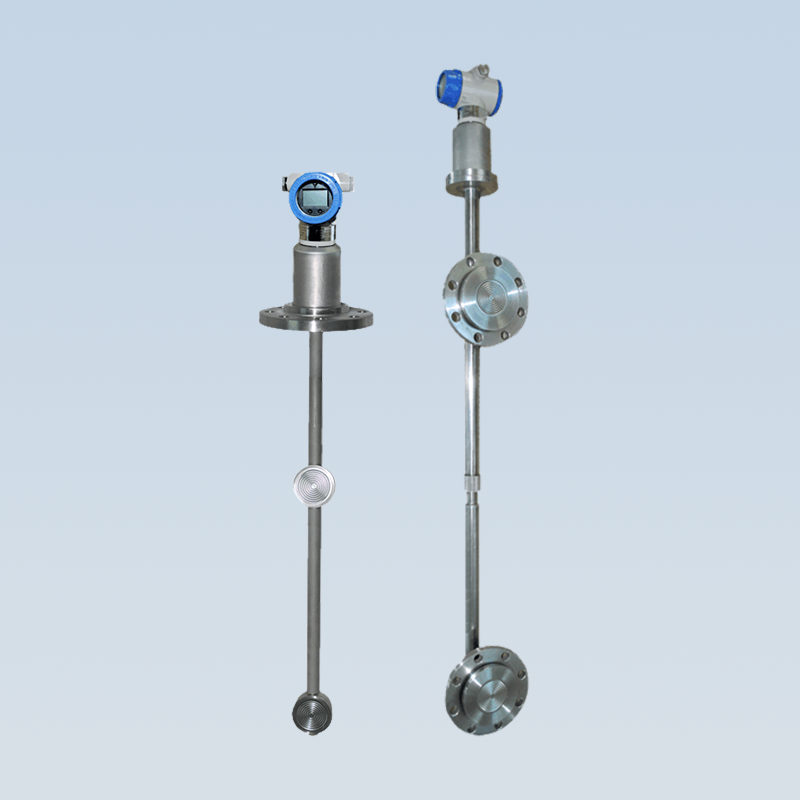

Top Mounted Liquid Density Meter

- Information

- Product Description

- Video

- Download

Production Introduction

Industrial top mounted liquid densitiy meter is a continuous on-line instrument for measuring liquid density, which is mainly used for industrial process automation control. The corresponding 4-20mA analog signal is generated according to the change of medium density, and the digital signal can be output through conversion for remote calibration and monitoring.

Production Features

stainless steel wetted components, safe and reliable

It is easy to install and use, and the reading can be displayed by inserting liquid.

Simplify maintenance without regular cleaning.

Top mounted liquid densitiy meter calibration requires no standard reference source, no laboratory calibration and no process interruption.

Intrinsically safe type can be used in hazardous sites The sanitary type can be installed on the food production site.

Product Parameters

Measurement Range: | Density: 0.000 – 5.000 g/cm31 |

Accuracy: | Density 0.5–2 g/cm3 |

Resolution: | ±0.005 g/cm3 |

Calibration Method: | User performed |

Temperature Range (Sample): | 0 – 100 °C (32 – 212 °F) |

Communication: | 4 – 20 mA, HART Protocol |

Display: | Digital LCD |

Operating Environment: | Temperature: -10 – 60°C (14 – 140°F) |

Power Requirements: | 15 – 30 VDC (24 VDC recommended) |

Dimensions: | Individual dimensions vary depending on model, volumetric displacement no more than 0.15 cm3 (0.01 in3) |

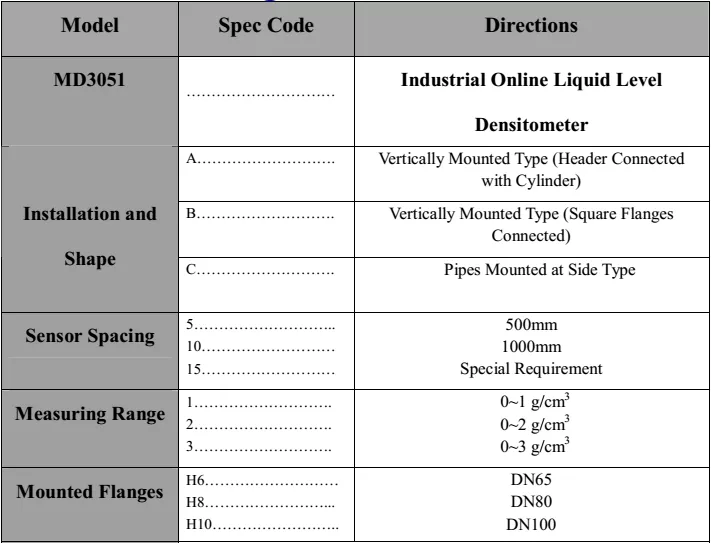

Product order sheet

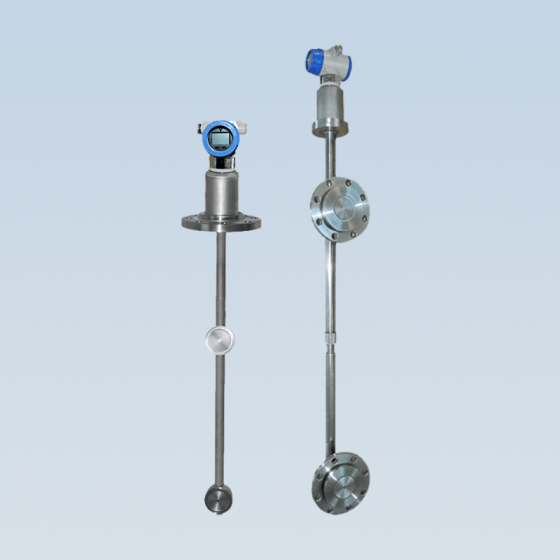

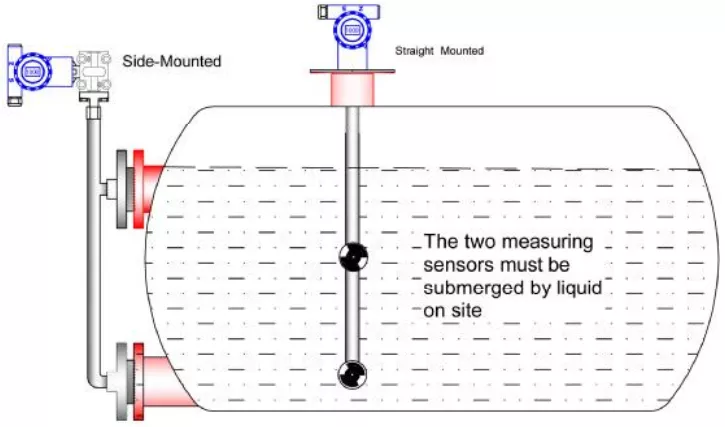

Product installation

Production line

2. The shape between the measuring tube of the density meter and the diaphragm seat is a bell mouth, which can avoid the retention of medium or gas, and avoid the direct impact of fluid on the diaphragm, thus extending the service life of the diaphragm.

3. For medium with large temperature change, we adopt temperature compensation to ensure the accuracy of density meter measurement.