The Elegant "Chlorine" Technique of Orifice Flowmeters: The Secrets to Measuring Chlorine Gas Flow

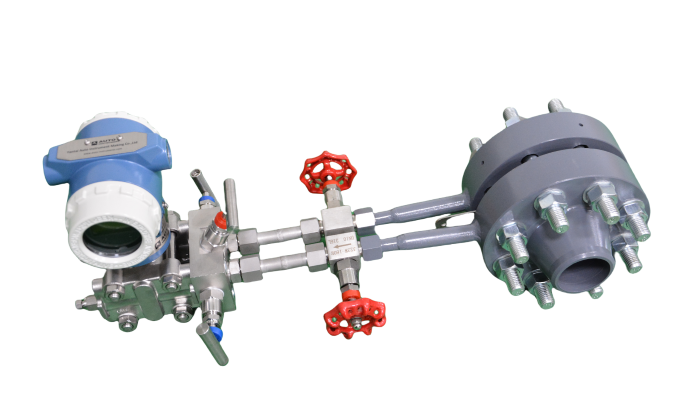

In the world of chemical factories, especially when dealing with gases like chlorine (Cl₂), which has quite the "bad temper," having a reliable companion is essential for worry-free production. The orifice flowmeter, an unsung hero with outstanding capabilities, is precisely designed to meet this challenge. Here are its "hidden strengths" when it comes to measuring chlorine gas flow. Let’s take a lighthearted look!

1. Corrosion Resistance: Coexisting Peacefully with Chlorine Gas

Chlorine gas: "I am toxic and highly corrosive, the 'king' of gases!"

Orifice Flowmeter: "Ever heard of Hastelloy C? Not only am I not afraid, but I can handle it with ease!"

The orifice flowmeter, with its "Hastelloy C armor" design, easily resists chlorine’s corrosive attacks, ensuring long-term stable operation. Using it means saying goodbye to frequent part replacements and worrying less!

2. Precision On Point: Flow Fluctuations? No Problem!

Chlorine gas flow fluctuates wildly, rising and falling like an unpredictable stock market. But the orifice flowmeter remains unphased, with its wide flow range of 240-1200 kg/h, coupled with the "superpower" of the AT3051DP differential pressure transmitter, it precisely manages any flow changes. For chemical factories, this is a top-notch performance!

3. High Pressure Endurance: Solid Like Steel

Under a working pressure of 3 kgf/cm², the orifice flowmeter remains rock-solid. Its design, with no moving parts, not only provides excellent pressure resistance but also eliminates issues caused by wear and mechanical failure. This makes it perfectly suited for high-pressure environments, handling it with ease and confidence.

4. Environmental Adaptability: A Versatile "Good Buddy"

Whether it's a 50mm pipe diameter or a mild 30°C working temperature, the orifice flowmeter shows no preference. With stable data output, you don’t have to worry about errors caused by temperature or size changes—it’s the epitome of reliability.

5. Top-notch Safety: Chlorine Gas Surrenders!

When facing toxic and hazardous chlorine gas, sealing performance is paramount. The orifice flowmeter, combined with PTFE gaskets and packing, acts as the "gas escape terminator." This level of safety ensures that chlorine gas gives up on causing any trouble.

Summary: The Treasure of Chlorine Measurement

The orifice flowmeter is that unassuming yet extraordinary presence. Its corrosion resistance, high precision, high pressure endurance, and long lifespan make it stand out in chlorine gas measurement. With it in a chemical plant, efficiency rises, safety becomes more stable, and it truly becomes the "protector of the factory."

So, to all the chemical plant folks out there, leave the chlorine measurement to the orifice flowmeter!