Analyzing the Structure and Customization Options of Differential Pressure Transmitters

2024-12-04 12:53

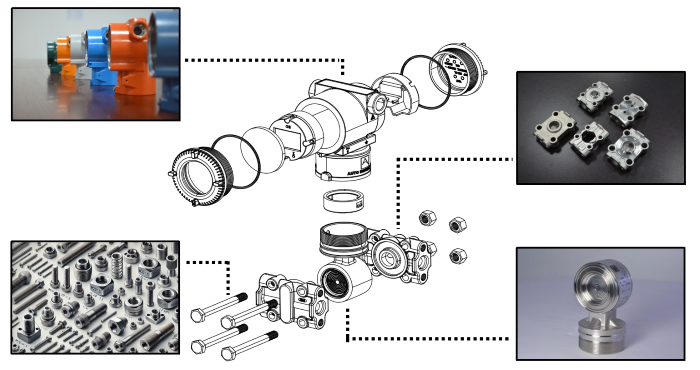

Differential pressure transmitters play a crucial role in industrial applications, that offering precise monitoring and control. A detailed breakdown of their components highlights their functionality and customization capabilities. These devices typically consist of four main parts: the head, sensor, flange, and bolts. Here's a closer look:

Head

Customization options: Available in various colors and molds to meet specific aesthetic or operational requirements.

Key benefit: Allows branding and integration into diverse environments.

Sensor

Features: Supports multiple measurement ranges and comes in different designs to accommodate specific use cases.

Versatility: Pressure sensors can be tailored to measure everything from low to high-pressure differentials with accuracy.

Traditional Flange

Types: Comes in diverse shapes, including designs with holes, ideal for level product.

Adaptability: Provides flexibility for integration into varied pipeline configurations.

Bolt Connections

Custom options: A wide range of sizes is available, including common threads like M20*1.5, 1/2NPT, and 1/4NPT. Both internal and external threads are offered.

Integration: Can be combined with valve sets, process flanges, and integrated connectors to suit complex setups.

Comprehensive OEM Support

AUTO instrument's OEM services offer full customization, backed by a team with over 30 years of industry expertise. Customers can provide on-site issues and dimension requirements, and our technical experts will tailor solutions to meet their needs.

Differential pressure transmitters are not just measuring instruments but versatile tools that can be adapted for specific operational demands. Contact us to discuss your customization needs and explore how our solutions can enhance your processes.