4-20mA Liquid Gas Air Vortex Flow Meter

- Information

- Product Description

- Video

Introduction - Vortex Flow Meter

The vortex flow meter is an advanced flow measurement device designed to measure the flow rate of various fluids, including liquids, gases, and steam. The vortex transmitter works by detecting vortices that form when fluid flows past a bluff body—a stationary element placed within the flow path. These vortices create alternating low- and high-pressure zones downstream, resulting in pressure fluctuations. A sensor inside the flow meter detects these pressure fluctuations and converts them into a frequency signal that reflects the flow rate.

In a specialized application like the LPG flow meter, the vortex flow meter’s sensor and transmitter work in perfect tandem to accommodate the unique properties of Liquefied Petroleum Gas (LPG). The piezoelectric sensor accurately detects the pressure fluctuations created by vortices as LPG passes the bluff body, ensuring stable and reliable readings even under variable flow conditions. The vortex transmitter then processes the piezoelectric signals into a precise, linear output that can be easily integrated into a process control system.

This robust design offers advantages such as low maintenance, high durability, and suitability for extreme temperatures and pressures, making vortex flow meters highly valued in industries like power generation, oil and gas, chemical processing, and HVAC. By providing accurate, real-time flow measurements, the vortex flow meter supports energy-efficient operations, safety monitoring, and optimal control over critical industrial processes.

Features

The vortex flow meter features a straightforward and durable design, simplifying installation and maintenance. It removes the need for impulse piping and a three-valve manifold, minimizing the risks of leakage, blockages, and freezing.

In terms of measurement precision, it achieves high accuracy, typically within ±(1 to 1.5)% of reading, making it suitable for applications requiring reliable data.

The display provides simultaneous readings of both instantaneous flow rate and cumulative flow, eliminating the need for alternating displays.

Engineered with a rational structure, the meter supports a broad dynamic measurement range and maintains minimal pressure loss, optimizing performance across varying flow conditions.

Product Parameters

Nominal diameter (mm) | 25,40,50,65,80,100,125,150,200,250,300,(300~1000 Insert type) |

Nominal pressure (MPa) | DN25-DN200 4.0(>4.0 Supply agreement),DN250-DN300 1.6(>1.6 Supply agreement) |

Medium temperature(°C) |

Piezoelectric type:-40~260,-40~320;Capacitance type : -40~300, -40~400,-40~450(Supply agreement)

|

Body material

| 1Cr18Ni9Ti,(Other materials supply agreement) |

Allowable vibration acceleration

| Piezoelectric type:0.2g Capacitance type:1.0~2.0g |

Accuracy

| ±1%R,±1.5%R,±1FS;Insert type:±2.5%R,±2.5%FS |

Range of

| 1:6~1:30 |

Power supply voltage |

Sensor:+12V DC,+24V DC;Transmitter:+12V DC ,+24V DC;Battery type:3.6V Battery

|

Output signal

| Square wave pulse ( not including the battery power supply type ): high level or low level5V,1V; current: 4~ 20mA |

Pressure loss coefficient

| In line with the JB / T9249standard Cd = 2.4 |

Explosion proof marks

| Intrinsic safety type: Exd IA CT2-T5 flameproof type: Exd CT2-T5 |

Protection grade

| The ordinary IP65 diving type IP68 |

Environmental conditions

| Temperature - 20~ 55,5% ~ 90% of relative humidity, atmospheric pressure is 86 ~ 106kPa |

Applicable medium

| Gas, liquid, steam |

Transmission distance

| Three wire system pulse output type: < 300m, two line standard current output type (4 ~ 20mA ): load resistance less than 750ohm |

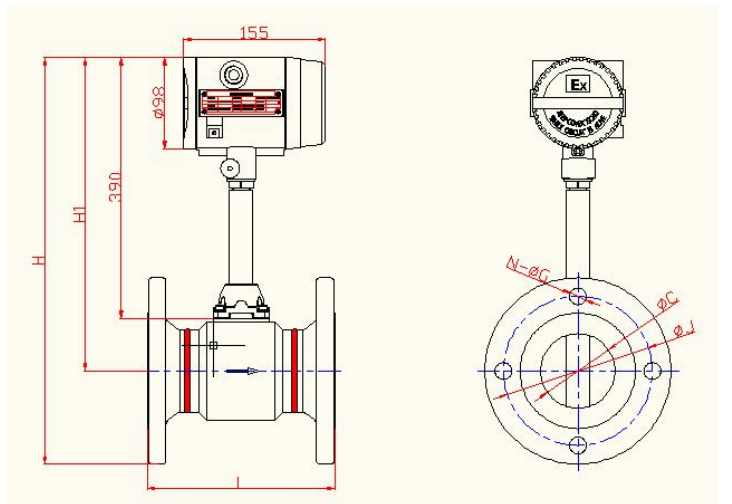

Product Detailed Images

Designed to excel in measuring liquids, gases, and steam with unparalleled accuracy, the vortex flow meter boasts a distinctive design that leverages vortex shedding for precise flow rate assessment. The vortex shedding flow meter's versatility extends across various industries, including oil and gas, chemical processing, and water treatment. The vortex flow meters stand out in applications involving the measurement of steam, compressed air, nitrogen, and other gases.

Product order sheet

LUGB | Explanation | ||

Nominal diameter (In mm) | diameter | DN15-300(Pipeline) | |

DN200-1500(Plug-in) | |||

Connection | Pipeline | FL | Flange connection |

JZ | Flange clamp | ||

Z | Special rules | ||

Insert | J | Simple Formula | |

Q | Ball type | ||

Accuracy | Pipe line | 10 | 1.0%R |

15 | 1.5%R | ||

Insert | 20 | 2.0%R | |

25 | 2.5%R | ||

Z | Special accuracy standards | ||

Temperature and pressure | S | T(S)P(S)At normal temperature and pressure | |

Z | T(Z)P(Z)Twin extreme pressure | ||

Communication protocol | N | No communication interface | |

H | HART protocol | ||

M | MODBUS protocol | ||

Output | 1 | No output | |

2 | Two-wire 4-20mA output | ||

3 | Pulse output | ||

D | DC12V | ||

Power supply | DB | Dual 12V power supply and battery | |

DD | DC24V | ||

B | Battery 3.6V power supply, no signal output uses only | ||

Sensor Material | S | 304Stainless steel | |

L | 316Stainless stee | ||

Core Component Materials | S | 304Stainless steel Probes | |

L | 316Stainless steel Probes | ||

Measuring medium | 1 | Gas | |

2 | Liquid | ||

3 | Saturated steam | ||

4 | Superheated steam | ||

Production Line of the Vortex Lpg Flow Meter