Smart Differential Pressure Transmitter HART

- Information

- Product Description

- Video

- Download

Brief Introduction

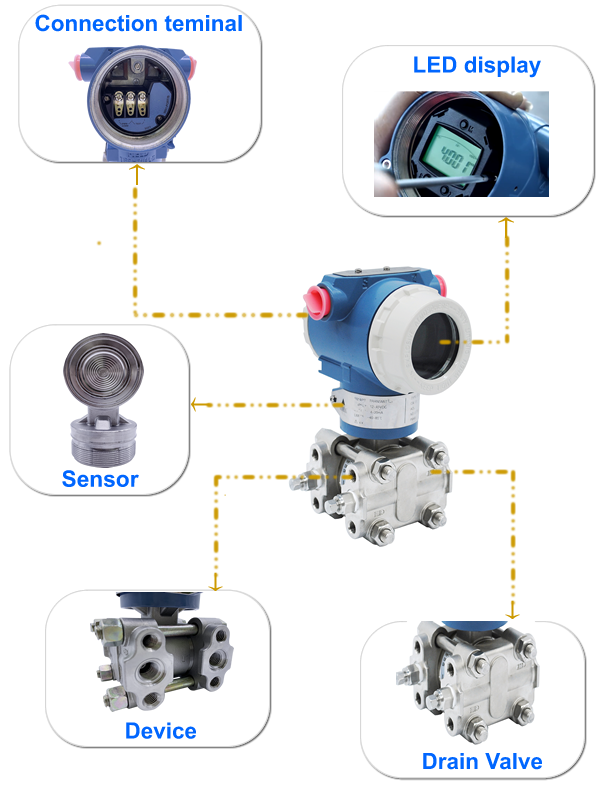

Differential pressure transmitter/pressure transmitter is a measure of the difference between the two ends of the transmitter ,output standard signal ( 4 ~ 20mA) differential pressure transmitter and pressure transmitter with the general difference is that there are two pressure ports, the differential pressure transmitter is generally divided into positive and negative terminal end, under normal circumstances, Positive pressure side pressure should be greater than the negative pressure section.

Features

Process Fluid: Liquid, gas, or steam flow as well as liquid level, density and pressure

Measuring range: 200Pa-10MPa

Working Temperature: -25 to +95C

Current Output: 4 – 20 mA 2 wires Hart Protocol

Power Supply: 24VDC

Ambient Temperature: -25 to +120C

Process connections: 1/4 – 18 NPT or 1/2 – 14 NPT

Electrical Connections: 1/2”NPT or M20*1.5

Enclosure:IP65

Intrinsically Safe: ia II C T6

Explosion proof: d II B T5

Diaphragm material: SUS316L, Hastelloy C

Industry application

Process control system

Petroleum industry

Chemical industry

Item | Code | Specification |

AT3051DP | Differential Pressure Transmitter | |

AT3051GP | Gauge Pressure Transmitter | |

Measurement Range | 2 | 0-0.1~1.5 Kpa |

3 | 0~7.5 Kpa | |

4 | 0~37.4 Kpa | |

5 | 0~186.8 Kpa | |

6 | 0~690 Kpa | |

7 | 0~2068 Kpa | |

8 | 0~6890 Kpa | |

9 | 0~20680 Kpa | |

Output | S | 4-20mA, HART Protocol, Linear output |

J | 4-20mA, HART Protocol, Square root output(Range≥5kpa) | |

Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

3 | Hastelloy C(range >3Kpa) Silicone Oil | |

A | Stainless Steel 316L Fluorine oil | |

Drain hole | B | Back of process flange or none |

U | Process flange side upper | |

L | Process flange side lower | |

Wetted O-ring Material | 7 | Buna-N (NBR) |

6 | Viton (FKM) (Temperature ≥-20℃) | |

5 | Low Temperature Viton (FKM-GFLT) | |

Process Connection | H | 1/4'' NPT F |

Maximum Pressure Limit | 1 | 14 Mpa( 4Mpa for range 2) |

3 | 25 Mpa | |

5 | 32 Mpa | |

Cable Entry | 1 | M20*1.5 or NPT1/2'' |

Mounting Bracket | B00 | None |

B01 | Tube-type Curved Bracket (carbon steel) | |

B02 | Wall mounting bracket (carbon steel) | |

B03 | Tube-type Flat Bracket (carbon steel) | |

B04 | Tube-type Curved Bracket (stainless steel) | |

B05 | Wall mounting bracket (stainless steel) | |

B06 | Tube-type Flat Bracket (stainless steel) | |

Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

i | Intrinsically safe (Exia IIC T4~T6) | |

M3 | LCD display | |

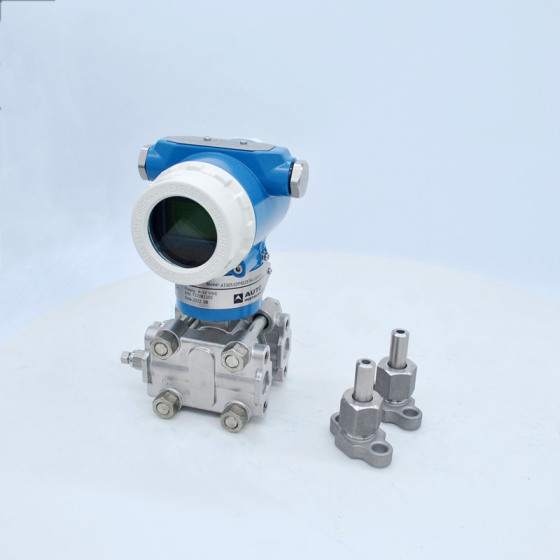

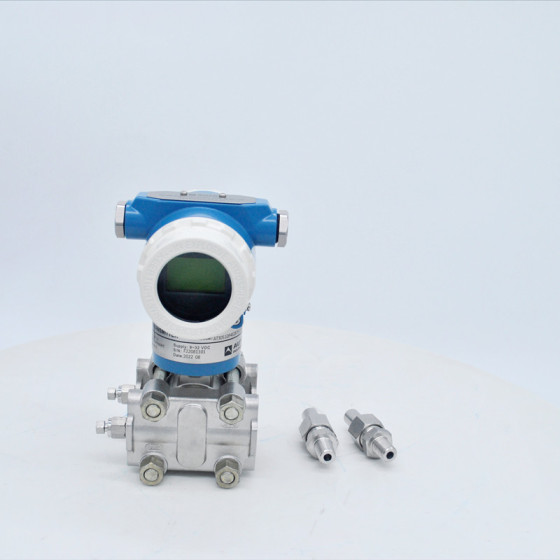

D1 | Stainless steel drain valve or screw (2pcs) | |

C1 | 1/2'' NPT female waist flange (2sets) | |

C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

C2 | M20*1.5 male thread T joint (2sets) | |

C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

K1 | Degreasing treatment | |

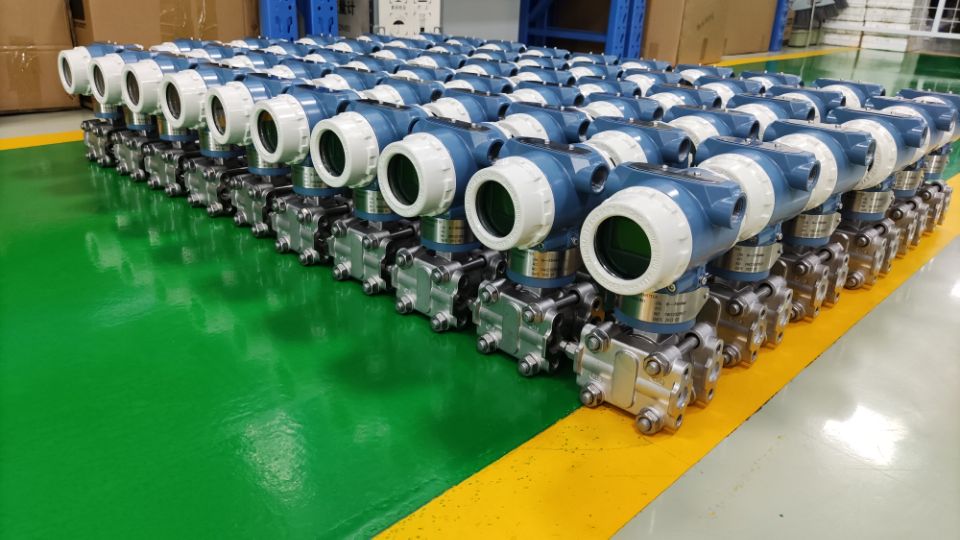

Production Line

Differential Pressure Transmitters Ready for Delivery

Differential Pressure Transmitters Applications

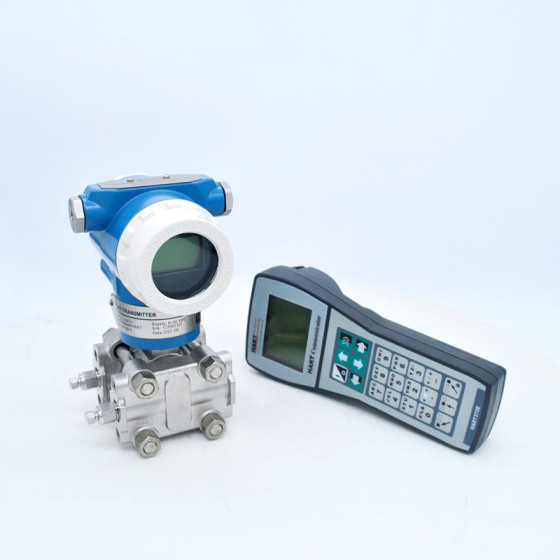

2. LCD display,HART communication of the pressure transmitter

3. Strong anti-interference ability.The variable device adopts 4-20mADC standard current signal output, two-wire system operation, with load and strong anti-interference ability.

4. Good overload performance. The inside of the sensor adopts a con-cave arc surface overload protection structure with simple structure and reliable performance.