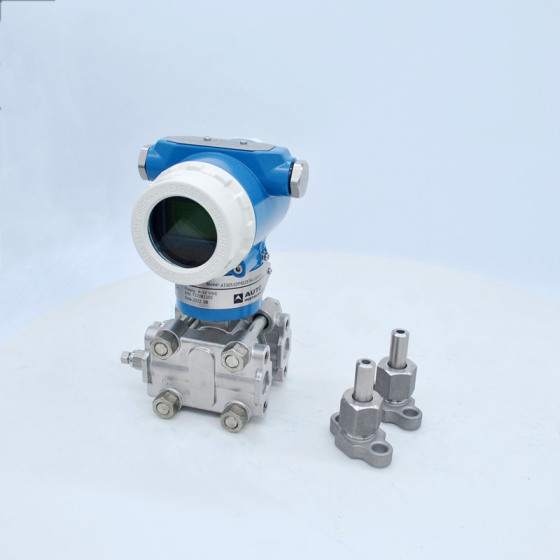

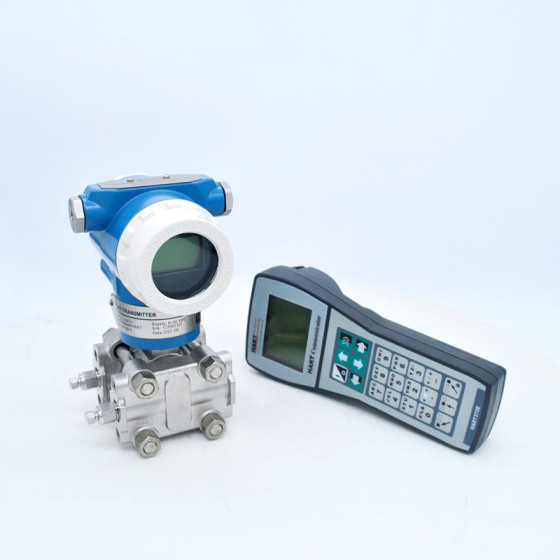

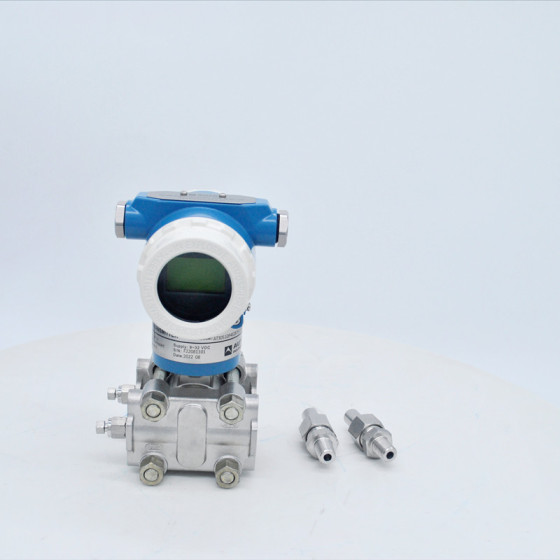

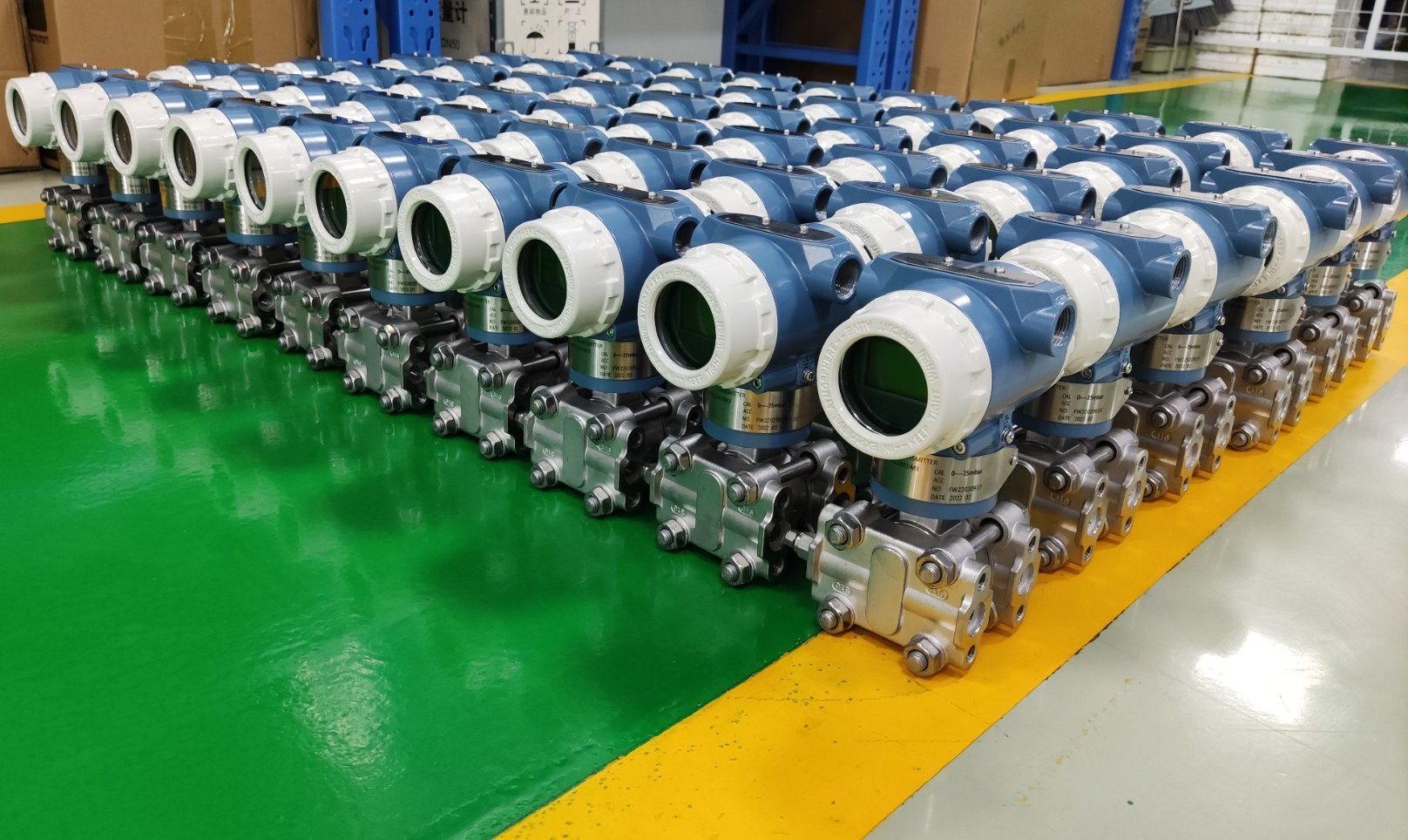

ATEX Approved Differential Sensor Pressure Transmitter

- Information

- Product Description

- Video

Dp Transmitter

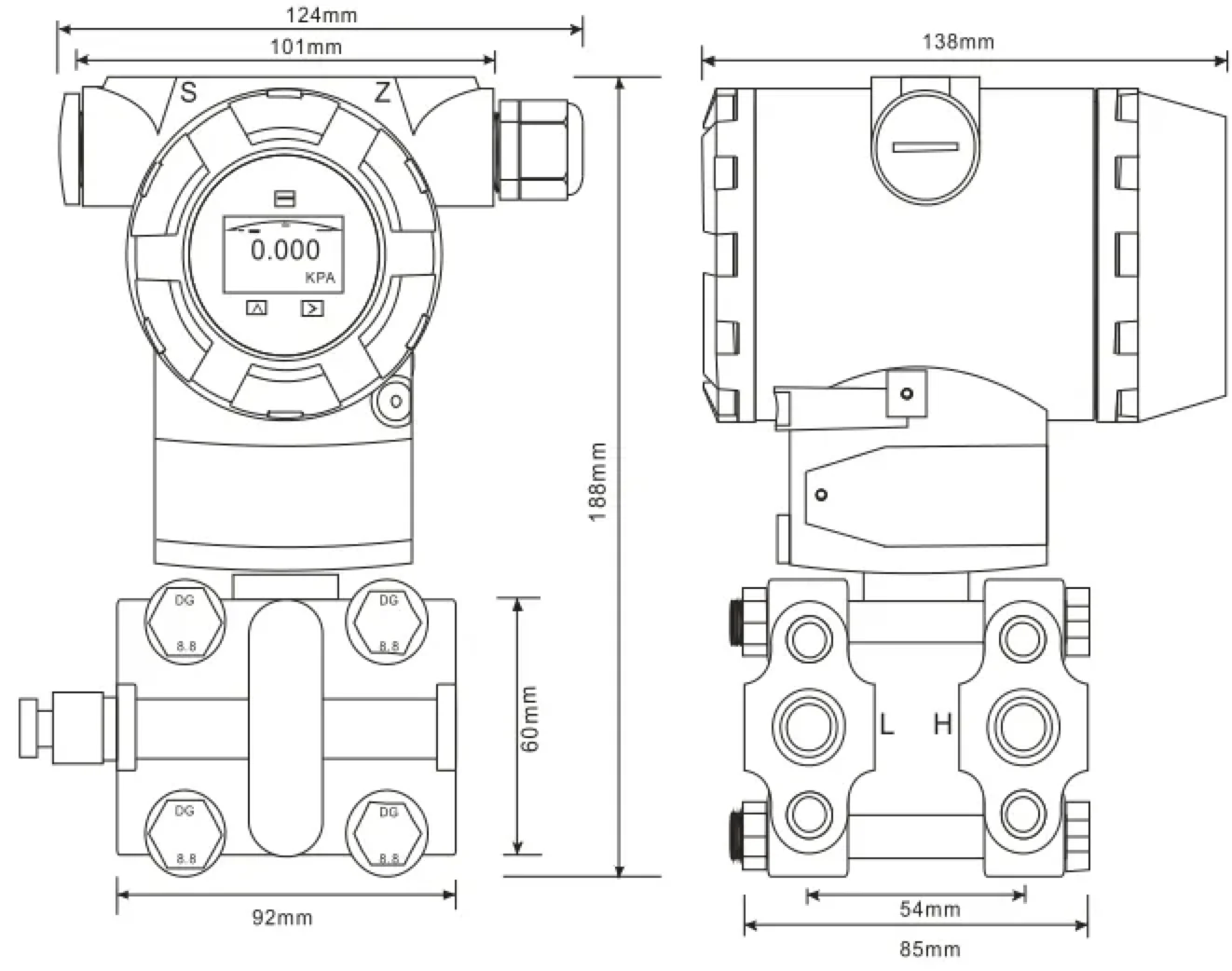

The 3051 series of advanced differential pressure transducer 4 20ma harness state-of-the-art capacitive sensor chips celebrated for their technological maturity. Esteemed by global users, these Dp pressure transmitters excel in measuring differential steam pressure. Employing sophisticated production methods and technologies, these differential steam pressure transmitters boast a modular architecture and maximize the utilization of all-patch-packaging components, culminating in a sleek and efficient design.

Introduction

The differential pressure transducer 4 20ma model acts as a device for measuring and transmitting the pressure of liquids or gases in a pipeline, tank, or vessel to a control system or display unit. Through capacitive technology, the dp transmitter converts the pressure into an electrical signal, enabling its transmission to a remote location for monitoring or control objectives.

Dp Pressure Transmitter Features

The dp pressure transmitter has the characteristics of good long-term stability, high reliability, and strong ability.

Intelligent pressure and temperature compensation safeguard the dp transmitter against temperature fluctuations and excessive pressure, thereby reducing potential measurement inaccuracies at the installation site.

The 3051 dp transmitter has extremely high anti-interference and stability.

The differential steam pressure transmitter uses a built-in temperature sensor.

The dp pressure transmitter's performance is improved by continuous monitoring of the sensor temperature and corresponding corrections.

Order Sheet

| Name | Specification Code | Description | ||

AT3051 GP AT3051 DP | Differential Pressure Transducer 4 20ma for Liquid, Gas, and Steam | |||

Measurement Range | 3 | (0.013 ~ 0.075) bar | ||

| 4 | (0.062 ~ 0.374) bar | |||

| 5 | (0.31 ~ 1.868) bar | |||

| 6 | (1.17 ~ 6.9) bar | |||

| 7 | (3.45 ~ 20.68) bar | |||

| 8 | (11.7 ~ 68.9) bar | |||

| 9 | (34.8 ~ 206.8) bar | |||

| 0 | (68.9 ~ 413.7) bar | |||

| Output Signal | E | Analog Type 4-20mA | ||

| S | 4-20mA, HART Protocol | |||

Wetted Parts Material | Flange/Joint | Exhaust/Drain Value | Diaphragm | |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

Mounting Bracket | B1 | Tube-type Curved Bracket (Tube ODΦ50~Φ60) | ||

| B2 | Board-type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50~Φ60) | |||

Display Header (optional) | M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header (0~100% scale) | |||

| M4 | LCD Header (0~100% linear display) | |||

| Process Flange | D | The liquid discharge / exhaust at the back | ||

| D1 | The liquid discharge / exhaust at the side top | |||

| D2 | The liquid discharge / exhaust at the side bottom | |||

| Flange Joint | J | "D-shaped" Joint with "M20*1.5" External thread | ||

| N | Joint with 1/2-14NPT Taper Pipe Thread Waist Type | |||

Pressure transducer 4 20mA is widely used in oil, food, electric plant, mechanic industry, pharmacy, etc.