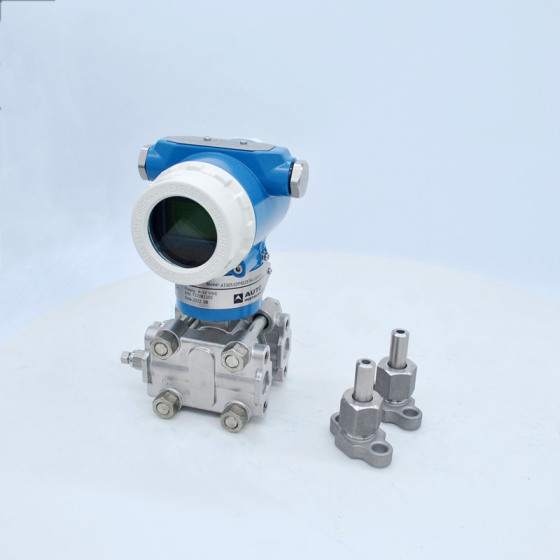

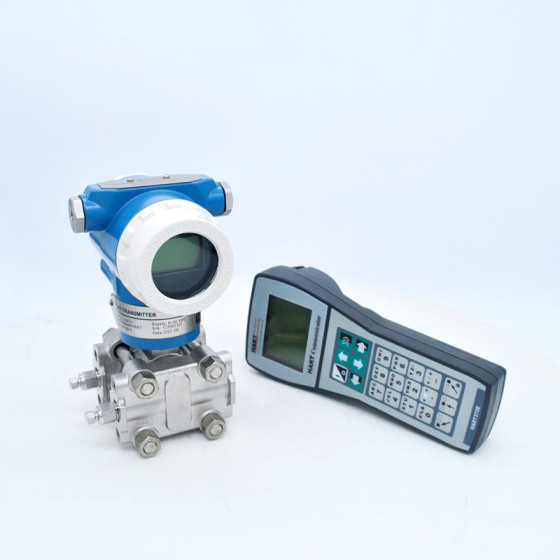

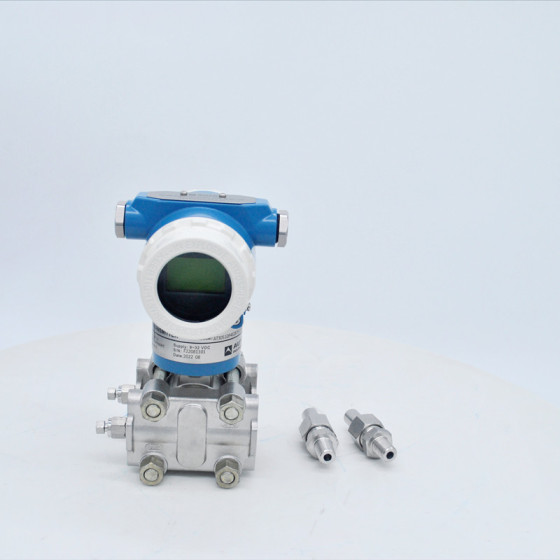

ATEX Explosion Proof Differential Pressure Transmitter

- Information

- Product Description

- Video

Introduction:

Smart pressure transmitter is a new-type intelligent instrument researched and developed by our company along with some internal companies under international advanced technology.

The dp transmitter has temperature and non linearity compensation under micro processing technology, improved meter measurement accuracy and temperature feature, expended the range ration, added the function of intelligent configuration, further meet the reliable and stable requirement for industrial field. Key component and parts are imported and strict test is done before delivery.The meter has advanced design principle,reliable product quality, variety,Simple installation and usage etc features.

Features:

Versatile measurement capabilities: Include pressure, differential pressure, liquid level, flow, and other relevant variables.

Advanced sensing technologies: Provide accurate and reliable measurements, and improve enhanced performance and precision.

Intelligent design and integration: the modular approach streamlines installation and maintenance processes, providing convenience and ease of use.

Wide industrial applicability: The transmitter finds extensive application across various industries, including petroleum, chemicals, electricity, metallurgy, and more.

Application:

Detection of process pressure in industrial fields

System for calibrating pressure in laboratory settings

Navigation and the construction of ships

Manufacturing and production of aircraft and aviation equipment

Operation and management of air separation plants and thermal power units

Managing and optimizing energy usage

Measurement and control system for hydraulic and pneumatic

Differential Pressure Transducer Order Sheet:

| Name | Specification Code | Description | ||

AT3051 GP AT3051 DP | Pressure Transmitter Differential Pressure Transmitter | |||

Measurement Range | 3 | (0.013-0.075) bar | ||

4 | (0.062-0.374) bar | |||

| 5 | (0.31-1.868) bar | |||

| 6 | (1.17-6.9) bar | |||

| 7 | (3.45-20.68) bar | |||

| 8 | (11.7-68.90) bar | |||

| 9 | (34.8-206.8) bar | |||

| 0 | (68.9-413.7) bar | |||

Output Signal | E | analog type 4-20mA | ||

| S | 4-20mA, HART Protocol | |||

Wetted Parts Material | Flange/Joint | Exhaust/Drain Valve | Diaphragm | |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

| Mounting Bracket | B1 | Tube-type Curved Bracket (Tube ODΦ50 ~ Φ60) | ||

| B2 | Board-type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50 ~ Φ60) | |||

| Display Header (optional) | M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header (0~100% scale) | |||

| M4 | LCD Header (0~100% linear display) | |||

Process Flange | D | The liquid discharge/exhaust at the back | ||

| D1 | The liquid discharge/exhaust at the side top | |||

| D2 | The liquid discharge/exhaust at the side bottom | |||

| Flange Joint | J | "D-shaped" Joint with "M20*1.5" External Thred | ||

| N | Joint with 1/2-14NPT Taper Pipe Thread Waist Type | |||

About Us:

1.Process Fluid: Liquid, Gas, Vapor

2.Application: Differential Pressure, Gauge Pressure, Absolute Pressure

3.Working Temperature: -25℃ ~ +95℃

4.Power Supply: 24VDC

5.Process connections: 1/4 - 18 NPT or 1/2 - 14 NPT

6.Electrical Connections: 1/2"NPT or M20*1.5