Intelligent Capacitive Differential Pressure Transmitter ATEX

- Information

- Product Description

- Video

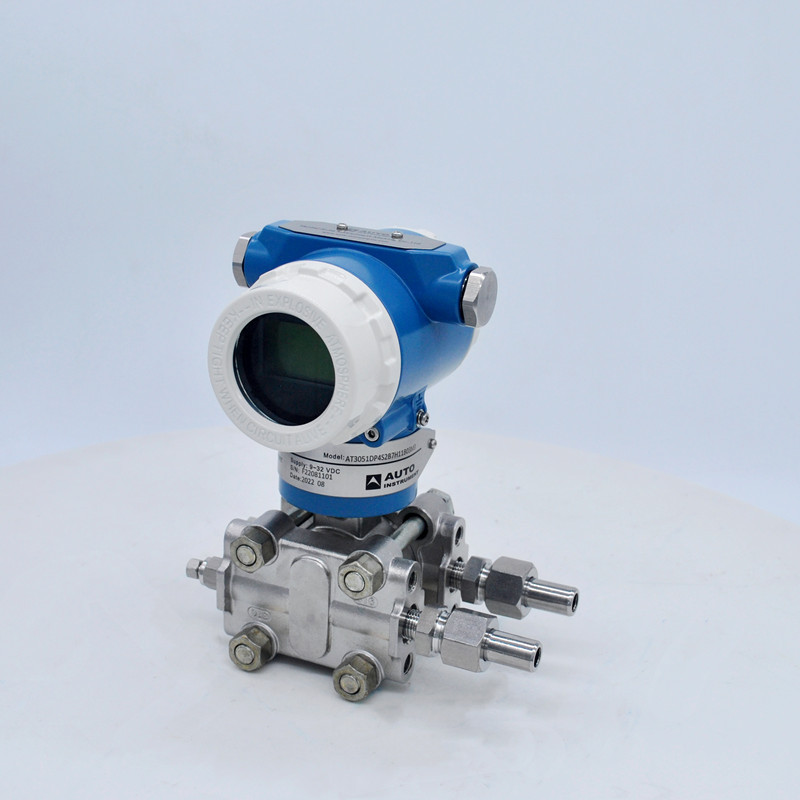

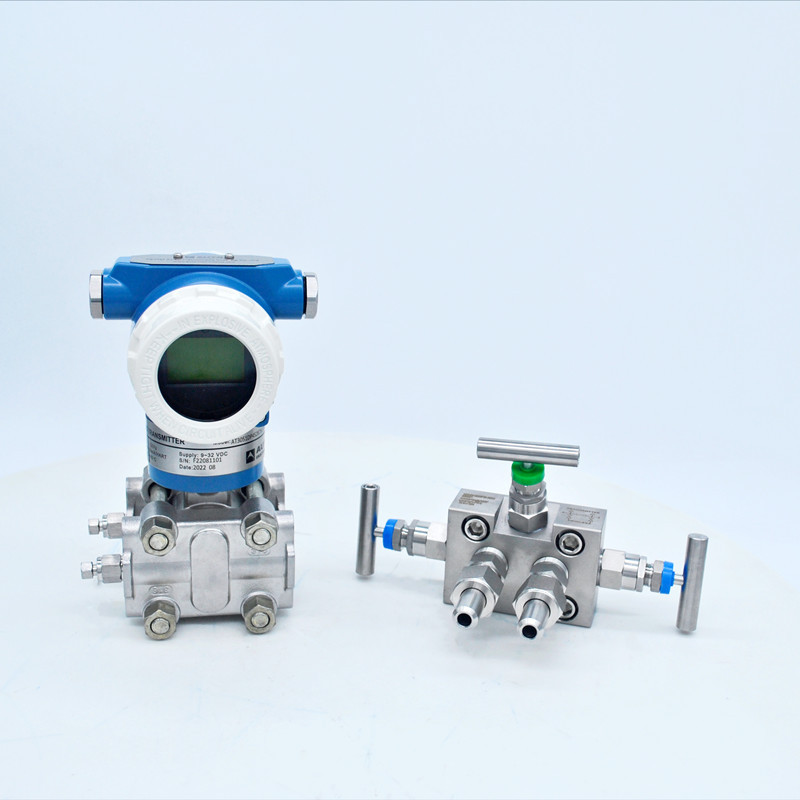

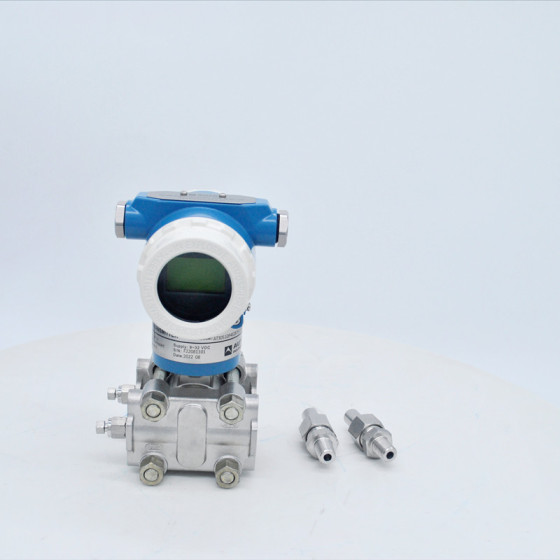

Smart Differential Pressure Transmitter

The differential pressure transmitter incorporates temperature and non-linearity compensation through microprocessing technology, enhancing meter measurement precision and temperature capabilities. The digital differential pressure transmitter expands the range ratio and incorporates intelligent configuration functions, thereby better fulfilling the reliability and stability demands of industrial settings.

The Features of Differential Pressure Transmitter HART

1. The smart differential pressure transmitters are capable of detecting the dynamic pressure of a fluid in real time with a fast response time.

2. The differential pressure transmitter HART adopts advanced sensing technology, which can ensure the accuracy of the measurement results.

3. The measuring range of the pressure transmitter differential can be adjusted according to the demand.

4. Differential pressure transmitter adopts advanced anti-interference technology, which can effectively resist the interference of external factors and ensure stable measurement results.

5. The reading system of the pressure transmitter differential is intuitive and easy to understand.

Application of the Pressure Transmitter Differential

Monitoring process pressure within industrial environments

Pressure calibration systems for laboratory applications

Navigation and shipbuilding

Fabrication and assembly of aircraft and aerospace components

Operation and oversight of air separation facilities and thermal power plants

Smart Differential Pressure Transmitter Order Sheet

| Name | Specification Code | Description | ||

AT3051 GP AT3051 DP | Pressure Transmitter Differential Pressure Transmitter | |||

Measurement Range | 3 | (0.013-0.075) bar | ||

4 | (0.062-0.374) bar | |||

| 5 | (0.31-1.868) bar | |||

| 6 | (1.17-6.9) bar | |||

| 7 | (3.45-20.68) bar | |||

| 8 | (11.7-68.90) bar | |||

| 9 | (34.8-206.8) bar | |||

| 0 | (68.9-413.7) bar | |||

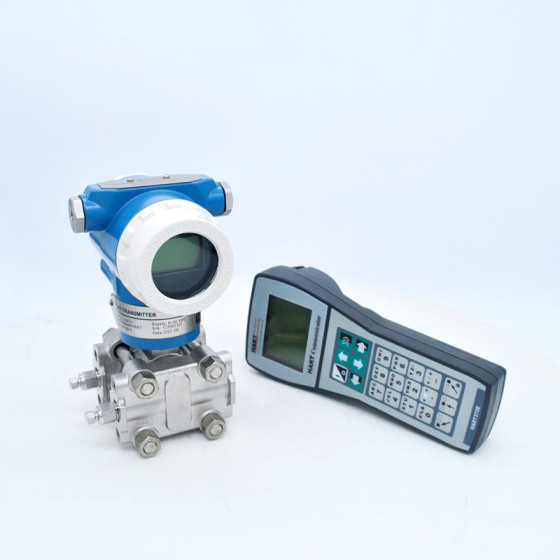

Output Signal | E | analog type 4-20mA | ||

| S | 4-20mA, HART Protocol | |||

Wetted Parts Material | Flange/Joint | Exhaust/Drain Valve | Diaphragm | |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

| Mounting Bracket | B1 | Tube-type Curved Bracket (Tube ODΦ50 ~ Φ60) | ||

| B2 | Board-type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50 ~ Φ60) | |||

| Display Header (optional) | M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header (0~100% scale) | |||

| M4 | LCD Header (0~100% linear display) | |||

Process Flange | D | The liquid discharge/exhaust at the back | ||

| D1 | The liquid discharge/exhaust at the side top | |||

| D2 | The liquid discharge/exhaust at the side bottom | |||

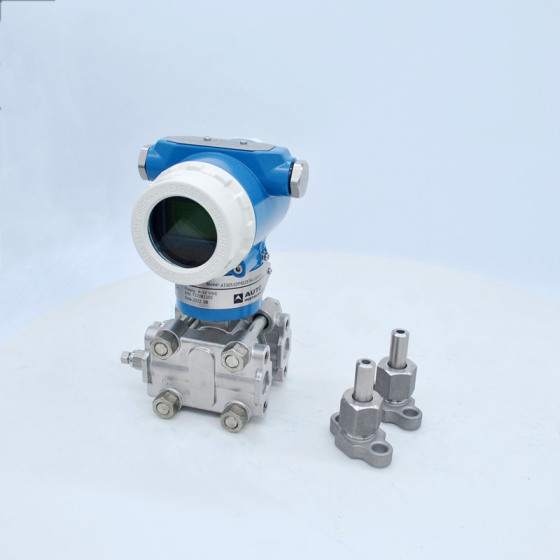

| Flange Joint | J | "D-shaped" Joint with "M20*1.5" External Thred | ||

| N | Joint with 1/2-14NPT Taper Pipe Thread Waist Type | |||

About Us

Key components and parts are sourced internationally and undergo rigorous testing before delivery. With its advanced design principles, reliable quality, versatility, straightforward installation, and user-friendly features, the meter stands out for its excellence.