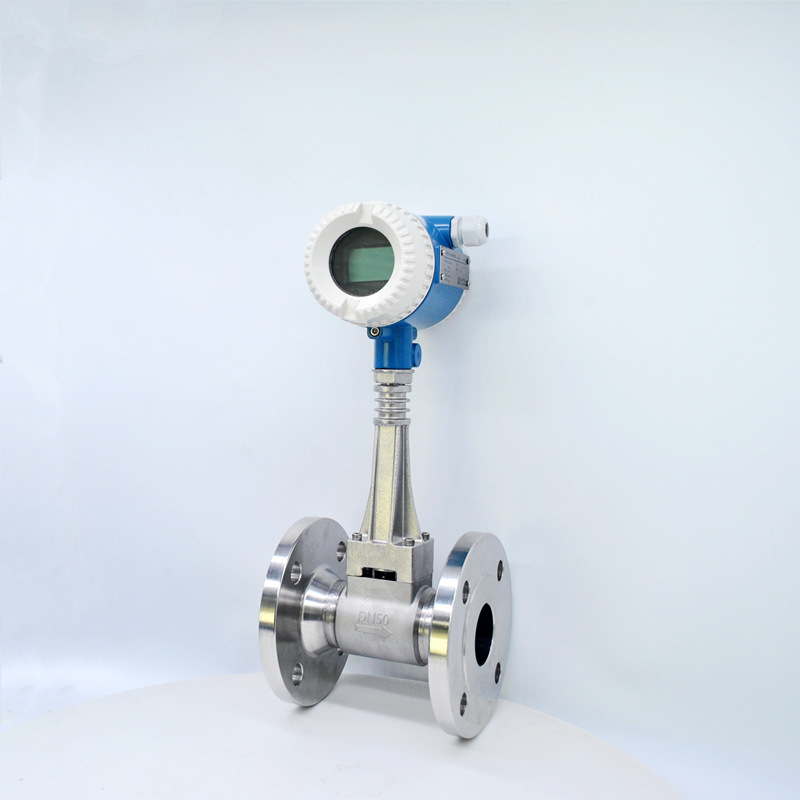

Stainless Steel Gas Vortex Shedding Flow Meter

- Information

- Product Description

- Video

vortex Flow Meter

Product Introduction

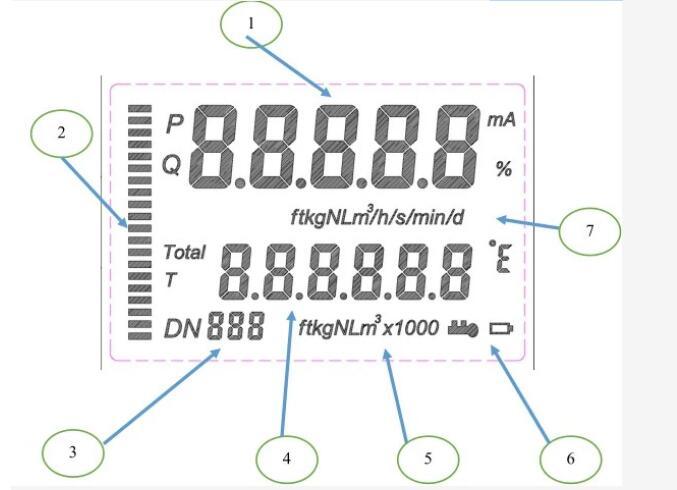

LUG series intelligent vortex steam flow meter is mainly used for flow measurement of industrial pipeline media fluids, such as gas, liquid, steam, and other media. The characteristics of the vortex vapor flow meter are small pressure loss, large measuring range, and high accuracy. The vortex flow meter is almost not affected by parameters such as fluid density, pressure, temperature, and viscosity when measuring the volume flow rate under working conditions.

Application

Application Areas:

1. Petrochemical industry: The vortex vapor flow meter can be used to measure the flow of various liquid and gaseous media in the process of petroleum and chemical production, such as crude oil, diesel fuel, gasoline, ethylene, acetylene, etc., as well as a variety of chemical substances.

2. Metallurgical industry: The vortex flow meter can be used in the metallurgical industry for flow measurement of gas and liquid media, such as oxygen, nitrogen, water vapor, etc.

3. Power industry: The vortex shedding flow meter can be used in thermal power plants, hydroelectric power plants, and other power industry flow measurements, such as boiler steam, cooling water, etc.

4. Food and pharmaceutical industry: The vortex steam flow meter can be used in food processing, beverage, and pharmaceutical industries for a variety of liquid media, such as water, sewage, steam, a variety of beverages, etc.

5. Water treatment industry: The vortex flow meter can be used in the water treatment industry, sewage treatment, drinking water treatment, circulating cooling water, and other liquid media flow measurement.

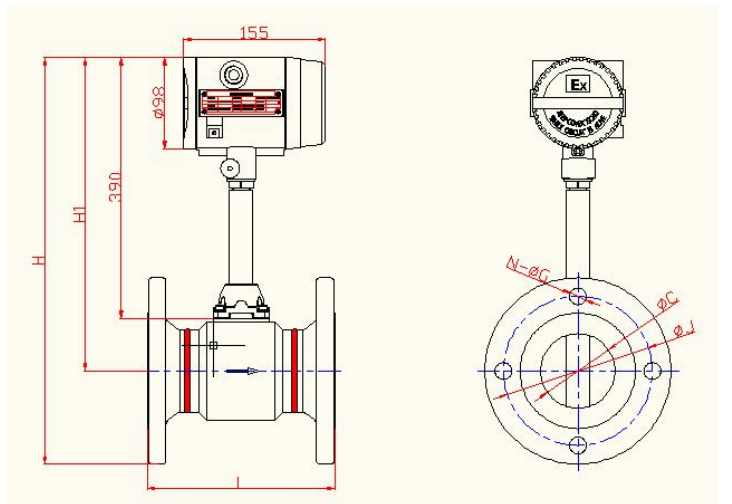

Product Parameters

Meter Diameter (mm) | Pipeline | Plug-in | ||

Liquid Measuring Range (m³/h) | Gas Measurement Range (m³/h) | Liguid Measuring Range (m³/h) | Gas Measurement Range (m³/h) | |

| DN20 | 1.2-12 | 6-50 | ||

DN25 | 1.6-16 | 8-60 | ||

DN32 | 2-20 | 12-120 | ||

DN40 | 2-30 | 20-200 | ||

DN50 | 3-50 | 30-300 | ||

| DN65 | 18-180 | 50-500 | ||

DN80 | 15-150 | 70-700 | ||

DN100 | 36-360 | 100-1000 | ||

DN125 | 36-360 | 150-1500 | ||

DN150 | 50-500 | 200-2000 | ||

DN200 | 100-1000 | 400-4000 | 70-700 | 600-6000 |

DN250 | 150-1500 | 600-6000 | 110-1100 | 1060-10600 |

DN300 | 200-2000 | 1000-10000 | 180-1800 | 1500-15000 |

| DN350 | 300-3000 | 1500-15000 | 210-2100 | 2000-20000 |

| DN400 | 350-3500 | 1800-18000 | 180-2700 | 2700-27000 |

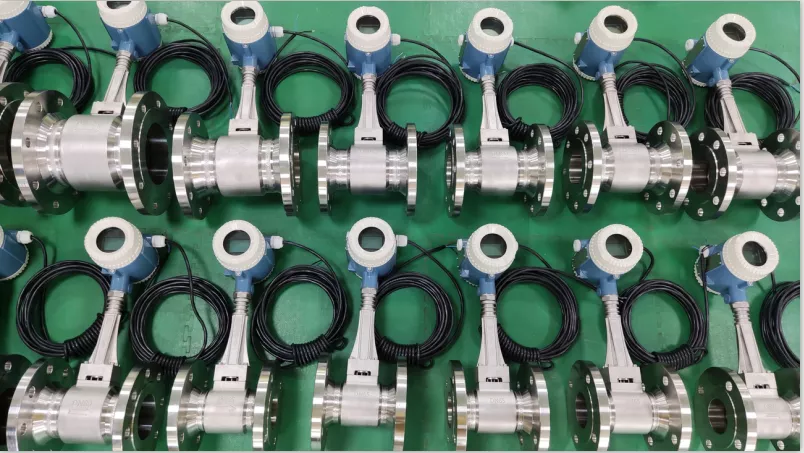

Product Detailed Images

Product Order Sheet

LUGB | Explanation | ||

Nominal diameter (In mm) | diameter | DN15-300(Pipeline) | |

DN200-1500(Plug-in) | |||

Connection | Pipeline | FL | Flange connection |

JZ | Flange clamp | ||

Z | Special rules | ||

Insert | J | Simple Formula | |

Q | Ball type | ||

Accuracy | Pipe line | 10 | 1.0%R |

15 | 1.5%R | ||

Insert | 20 | 2.0%R | |

25 | 2.5%R | ||

Z | Special accuracy standards | ||

Temperature and pressure | S | T(S)P(S)At normal temperature and pressure | |

Z | T(Z)P(Z)Twin extreme pressure | ||

Communication protocol | N | No communication interface | |

H | HART protocol | ||

M | MODBUS protocol | ||

Output | 1 | No output | |

2 | Two-wire 4-20mA output | ||

3 | Pulse output | ||

D | DC12V | ||

Power supply | DB | Dual 12V power supply and battery | |

DD | DC24V | ||

B | Battery 3.6V power supply, no signal output uses only | ||

Sensor Material | S | 304Stainless steel | |

L | 316Stainless stee | ||

Core Component Materials | S | 304Stainless steel Probes | |

L | 316Stainless steel Probes | ||

Measuring medium | 1 | Gas | |

2 | Liquid | ||

3 | Saturated steam | ||

4 | Superheated steam | ||

Production Line

1. The vortex steam flow meters can be used in almost all situations where vortex arrays can be formed, not only in closed pipes but also in open trenches.

2. The vortex vapor flow meters have a wide range of applications and can measure gases, liquids and steam.

3. The vortex flow meter has a large measurement range, small pressure loss, and high accuracy. It does not require a pressure guiding pipe and is easy to install and maintain.