4-20ma Remote Seal Flange Diaphragm Level Transmitter

- Information

- Product Description

- Video

- Download

Brief Introduction

Remote seal diaphragm level transmitter usd an isolated capacitive sensor, Using advanced technologies and processes such as laser correction, temperature compensation, and intelligent processing of analog signals, it has characteristics of high precision, good reliability, fast response speed, and stable performance. The product is simple in structure, easy to install, use and maintain.

Flange mounted level transmitter is a new generation of chemical anti-corrosion pressure detection and control instruments. It has strong anti-interference ability and suitable for long-distance signal transmission. It is well received by designers and users.

Features

Output signal: 4~20MA.DC two-wire system (analog)

The digital signal is superimposed on the two-wire 4~20mA DC signal, and the user selects the linear or square root output. (intelligent)

Power supply: 24V.DC

Load influence: When the power supply is stable, there is no load influence.

Measurement accuracy: reference accuracy 0.075%

Damping: usually adjustable between 0.1 and 16 seconds, when filling with inert liquid or with a remote transmission device, the time constant will increase.

Start-up time: <2 seconds, no warm-up required

Industry application

Oil and gas

Chemical

Metallurgy

Pharmaceutical

Electricity

Light industry

Order Sheet

| Item | Code | Specification |

| AT3051LT | Diaphragm differential level transmitter | |

| Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output | S | 4-20mA, HART Protocol, Linear output |

| Sensor Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

| Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

| Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

| Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

| Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

| Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

| Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

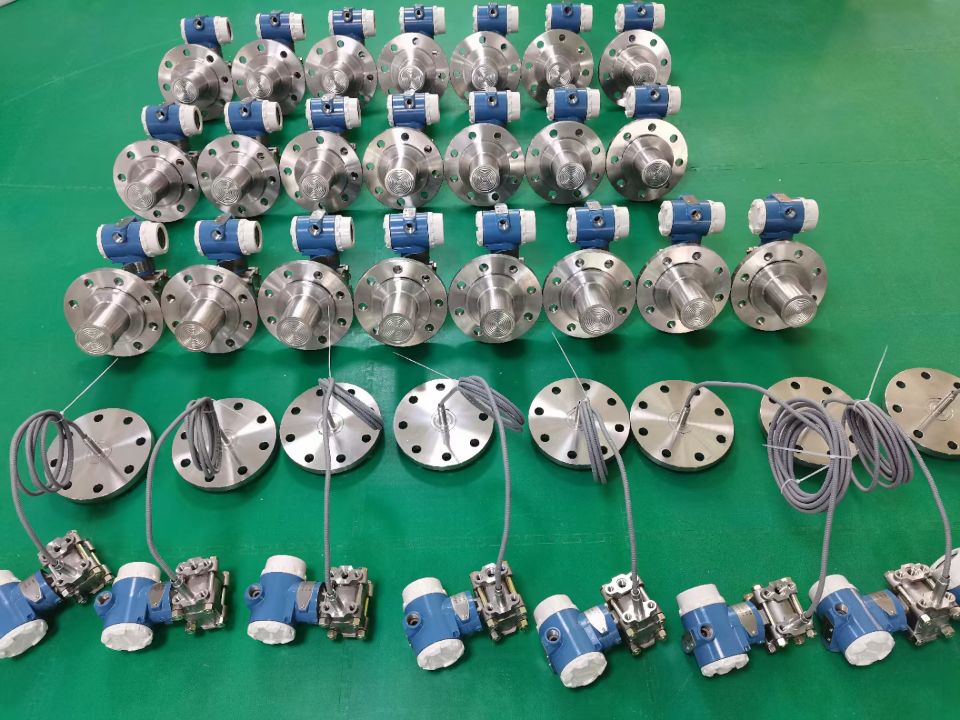

Production Line

Flange mounted level transmitterApplications

2. Flange mounted level transmitter with a variety of optional filling fluids. Span,zero external continuously.