Smart Remote Seal Flush Tank Level Transmitter

- Information

- Product Description

- Video

- Download

Brief Introduction

Flush pressure transmitter is used to measure the pressure, liquid level or density of liquids, gases or vapors. Using fully sealed capacitor or silicon differential pressure sensor, the pressure measurement has a high accuracy measurement while guaranteeing excellent stability and reliability. 3501 series products can be configured with HART communication protocol, which can communicate with the control system or hand operated device , through which setting, monitoring, testing and configuration can be carried out. HART protocol uses industry standard BELL202 frequency phase shift keying (FSK) technology to realize communication by superimposing digital signals on 4 ~ 20mA signals, the frequency signals do not interfere with 4 ~ 20mA signals when communicating.

Features

Smart pressure transmitter for measuring pressure, level, etc.

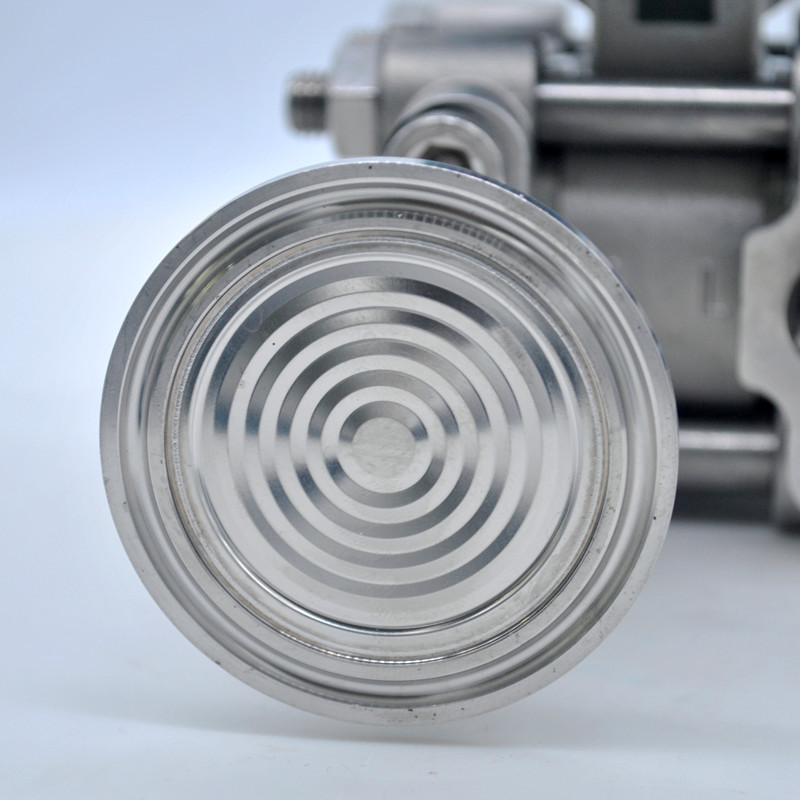

All welded metal diaphragm sensor.

Tri clamp connection, compact. structure design, saving installation cost.

Intuitive menus greatly simplify commissioning.

Industry application

Hydraulic and pneumatic control system, liquid level measurement and control

Petrochemical, Environmental protection(CEMS)

Power station operation patrol inspection and Locomotive braking system

Industrial process inspection and control

Building automation, Constant pressure water supply, Automatic control and Detection system

Order Sheet

| Item | Code | Specification |

| AT3051LT | flush pressure transmitter | |

| Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output | S | 4-20mA, HART Protocol, Linear output |

| Sensor Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

| Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

| Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

| Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

| Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

| Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

| Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

Production Line

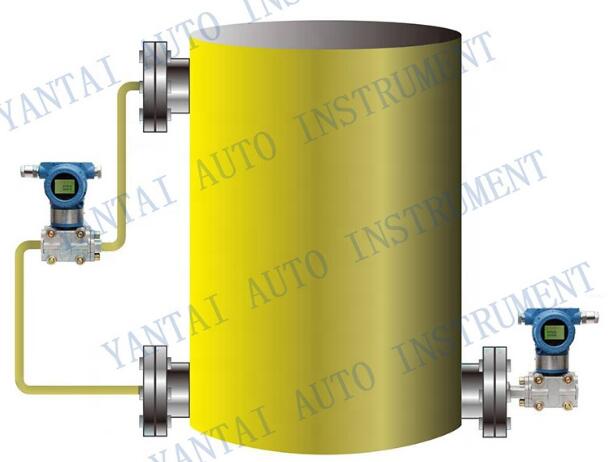

remote seal pressure transmitter Applications

2. Long-term stable performance,is safe and reliable, and is suitable for long-term use. lt is less affected by temperature changes and has strong anti-interference.