Single Flange Differential Liquid Level Transmitter

- Information

- Product Description

- Video

- Download

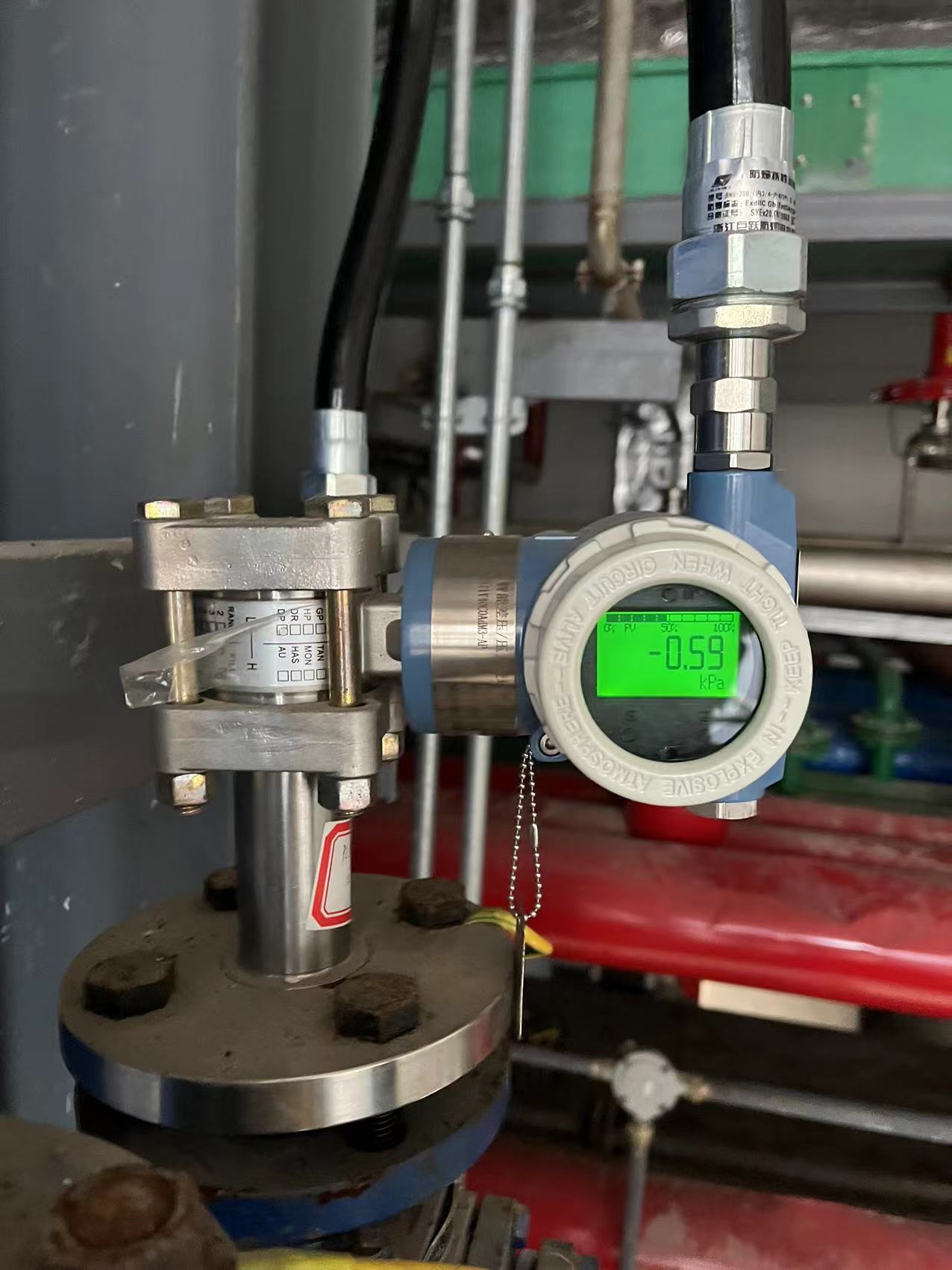

Brief Introduction

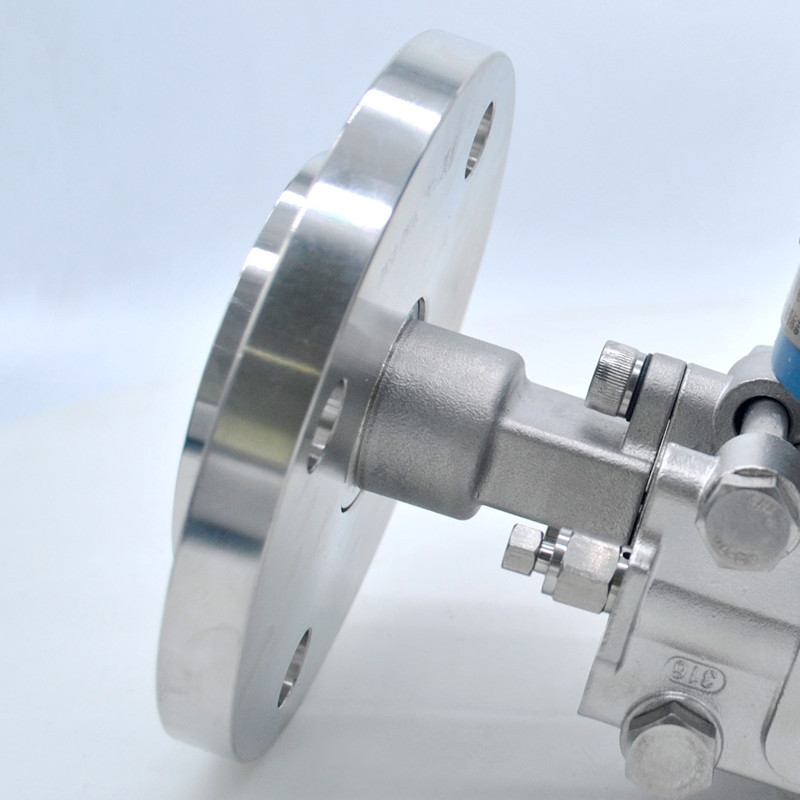

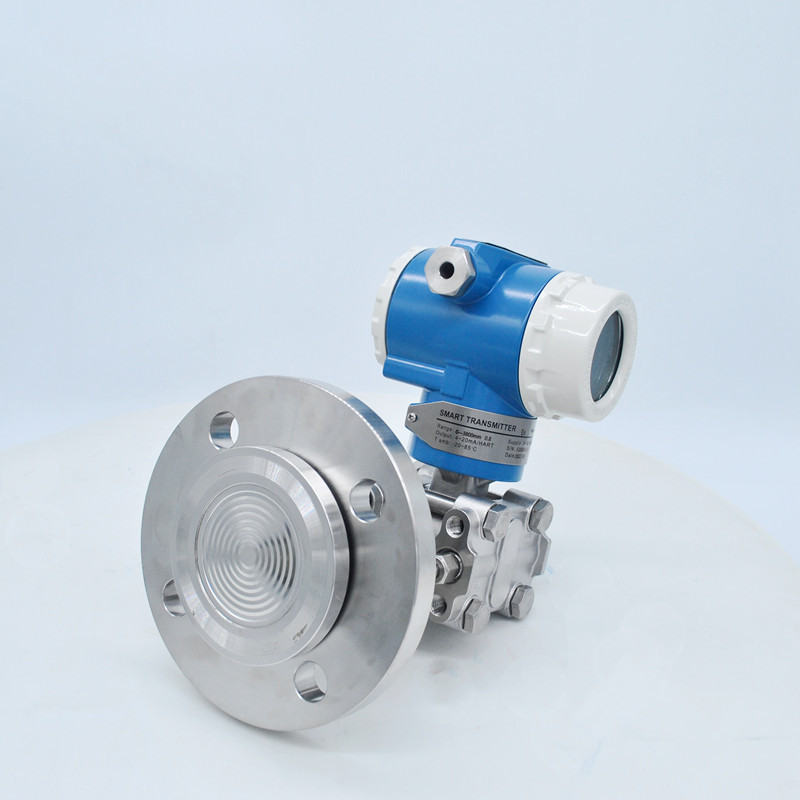

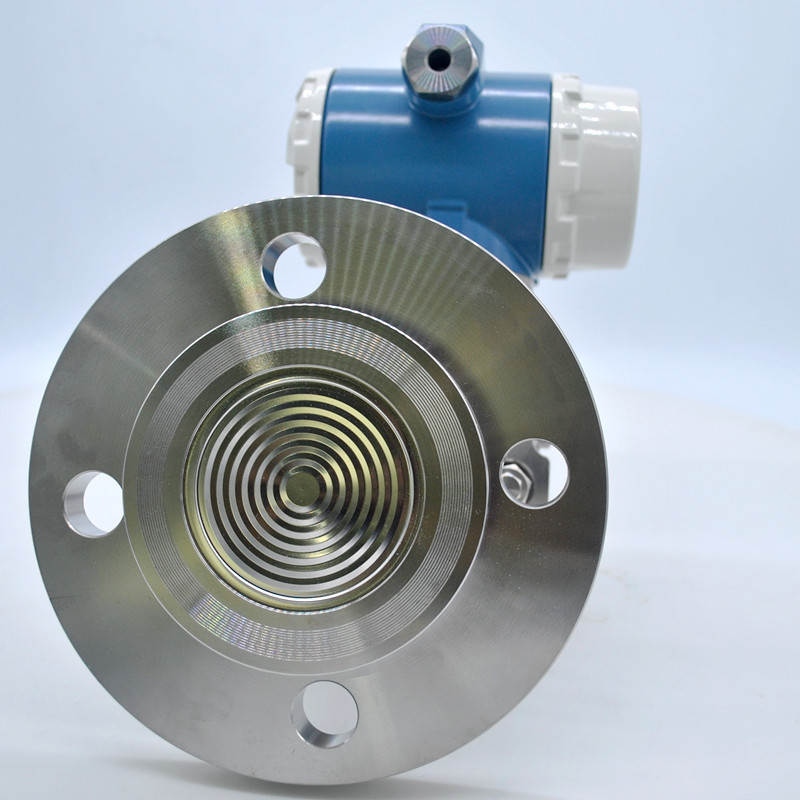

The single flange level transmitter is an industrial instrument for measuring liquid, slurry, or gas pressure, mainly used for level measurement. Flange level transmitter senses the pressure change of the liquid on the flange through the isolation diaphragm and converts the pressure signal into a standard electrical output (such as 4-20mA) for process control or monitoring systems. The flange design ensures that the medium does not come into direct contact with the internal components of the transmitter, effectively coping with corrosive or high-temperature media.

The Lt-type flange mounted pressure transmitter is mounted and connected using standard flanges for easy integration with a wide range of industrial equipment. The 4-20ma level transmitter's design is suitable for harsh working conditions and is widely used in the chemical, pharmaceutical, petroleum, food and beverage, and water treatment industries, especially in handling solid particles, mud, and easily blocked media, where differential level transmitter has significant advantages.

Features

Maximum reference accuracy: ± 0.075% calibration range

Stability: 6 months, ± 0.1% URL

Static pressure: 13.79mpa

Isolation film: 316 stainless steel, HC, Monel, tantalum

Stability: 6 months, ± 0.1% URL

Current output: 4-20 mA 2-wire Har t protocol

Power supply: 24VDC

Damped time constant: The time constant is adjustable in 0.1 second incrementsfrom minimum to 16 seconds

Order Sheet

| Item | Code | Specification |

| AT3051LT | flange mounted pressure transmitter/differential level transmitter | |

| Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output | S | 4-20mA, HART Protocol, Linear output |

| Sensor Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

| Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

| Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

| Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

| Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

| Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

| Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

Production Line

single flange level transmitter Applications

Flange mounted pressure transmitter is widely used in petroleum, chemical industry, metallurgy, electric power, food, paper, pharmaceutical, machinery, manufacturing and other industries.