Remote Diaphragm Seal Pressure Transmitter 4 20ma

- Information

- Product Description

- Video

Introduction:

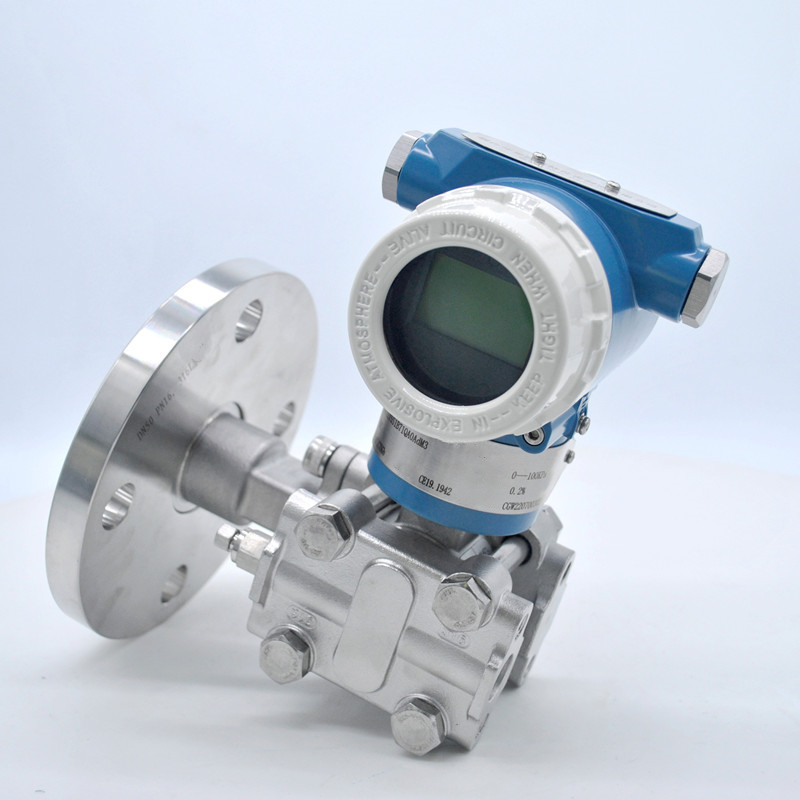

Remote Diaphragm Seal Pressure Transmitter 4 20ma

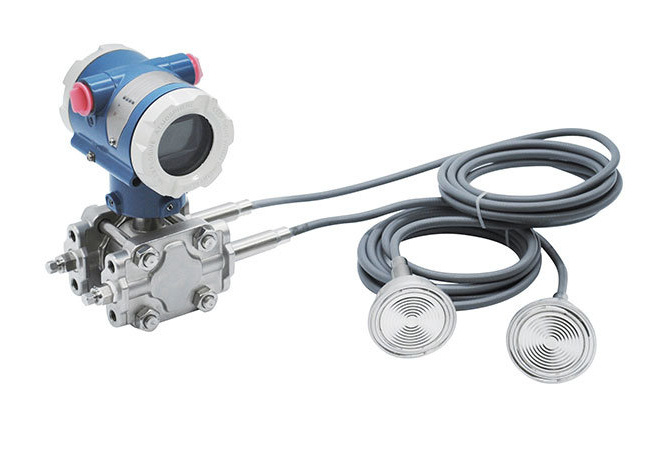

Diaphragm seal system consists of a gauge of differential pressure transmitter with one or two diaphragm seals. Suitable for various kinds of pressure measurement.

Flange level transmitter is used to measure the level and density of liquids with solid and sediment, then convert into 4-20mA current signal output. Available to connect with Hart Protocol for data monitor and control.

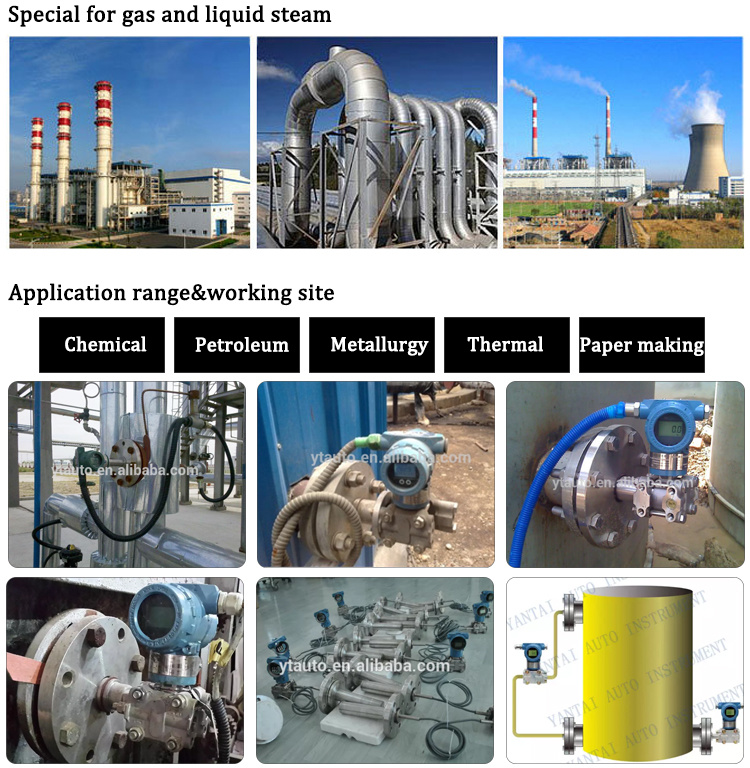

Diaphragm pressure transmitters widely used in petroleum, chemical, metallurgy, electric power, food, paper, pharmaceutical, machinery, manufacturing, and other industries.

Features:

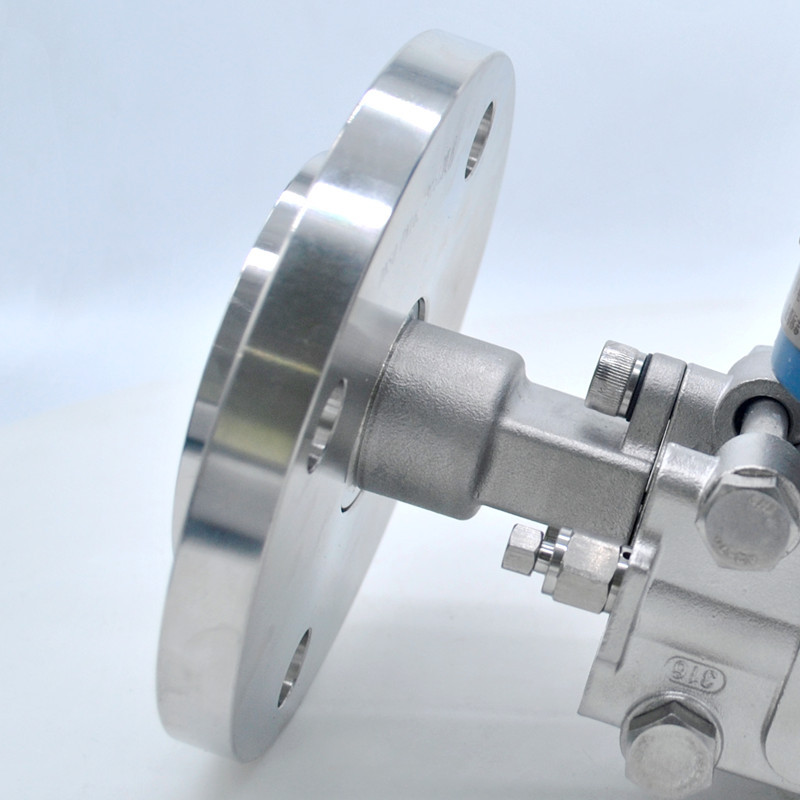

Versatile connection options like Tri-Clamp or union screw, are specifically designed for the food industry.

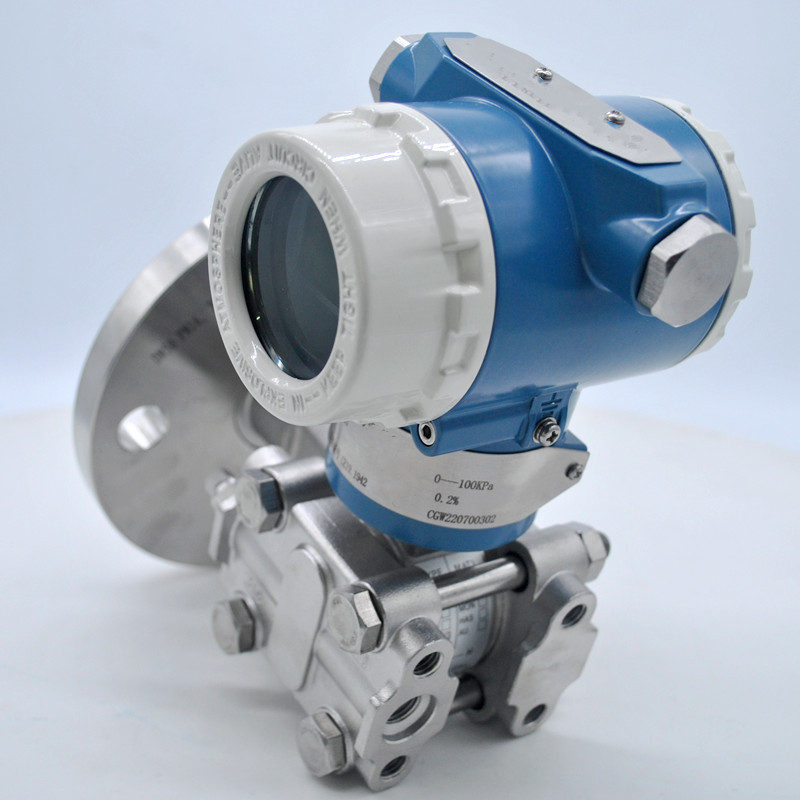

Exhibits a quick and agile response, delivering prompt and dynamic reactions.

Enhanced performance, heightened accuracy, and exceptional stability.

Work stably and reliably at extreme ambient and medium temperatures.

For Measurement of:

High/Low temperature fluids

High corrosive/viscosity fluids

The fluids which may cause clogging of impulse piping in the low temperature

Toxic fluids

The 3051LT level transmitter is used for measuring the level and density of liquids that encompass solids and sediment. Then it converts this information into a signal output ranging from 4 to 20 milliampere direct current (mA DC). Additionally, the 3051LT transmitters have the function of establishing communication among themselves using a HART Communicator. This facilitates tasks such as configuration and monitoring, etc.

Application:

Order Sheet:

| Name | Specification code | Description |

| AT3051LT | Smart Level Transmitter | |

Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output Signal | S | 4-20mA, HART Protocol, Linear output |

Sensor Diaphragm Material/ Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

Packing & Shipping:

The remote diaphragm seal pressure transmitter is simple in structure, easy to install, use and maintain, and suitable for long-distance signal transmission.

The remote diaphragm seal pressure transmitter is not easily damaged, and the accuracy will not be affected after long-term work.