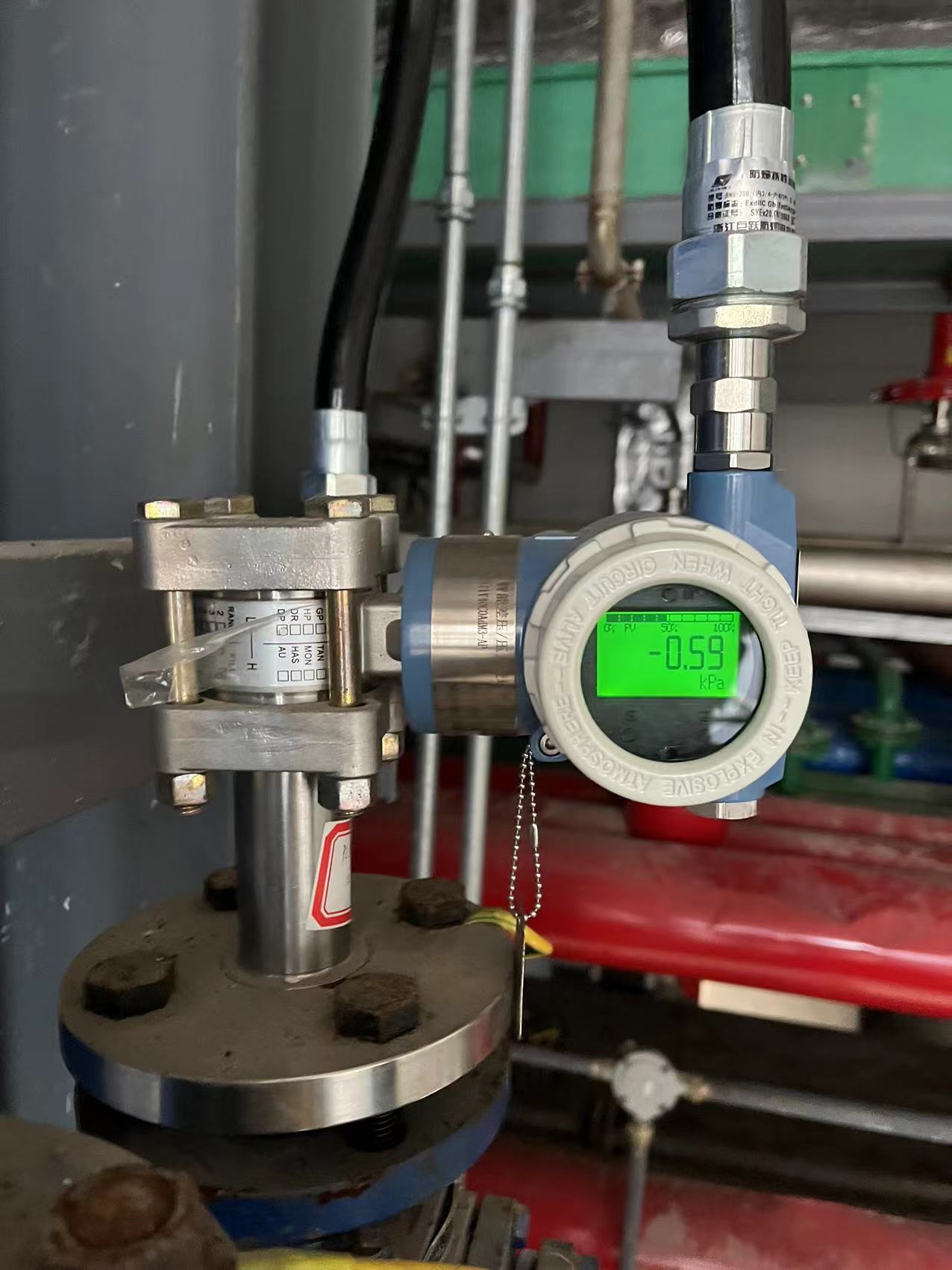

Remote Seal Flange Tank Level Transmitter

- Information

- Product Description

- Video

Brief Introduction

Features

Liquid level in open or sealed containers.

The reference accuracy of liquid level measurement is 0.075%.

Measuring range: 6kPa~2000kPa.

2-inch, 3-inch, 4-inch flat diaphragm or extended diaphragm.

A variety of filling fluid options are available to meet various application requirements.

Damping is adjustable.

Wetted Level Materials: Stainless Steel, Hastelloy C-276 and Tantalum.

Industry application

Oil and Gas Industry - In oil and gas separation, tank level monitoring, and downhole operations, the flush diaphragm pressure transmitter handles high-pressure and high-temperature environments, while also accommodating viscous media and corrosive gases common in oil fields. Capillary level transmitter's durability and remote monitoring capabilities support precise data collection on offshore platforms, pipelines, and refineries.

Chemical Industry - This field often involves acidic, alkaline, and highly corrosive media. The diaphragm seal pressure transmitter's direct contact design provides accurate measurements while avoiding corrosion issues associated with traditional pressure-guiding tubes. Flush diaphragm pressure transmitter is particularly suitable for measuring crystallizing and precipitating liquids, such as saline solutions and acidic or alkaline solutions.

Pharmaceutical and Food Industry - In pharmaceutical and food processing, strict sanitary conditions are required. The differential level transmitter's design without a pressure-guiding tube reduces contamination risk and is easy to clean. It effectively measures high-viscosity fluids such as syrups, concentrates, and emulsions, meeting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) requirements to ensure hygiene and safety.

Water and Wastewater Treatment - The capillary level transmitter is used in wastewater and water treatment plants to monitor levels and pressure, handling media with suspended solids and sediments. Its corrosion-resistant design adapts well to chemical treatments in water, providing stable support for quality control and monitoring.

Power Industry - In power plants, this pressure transmitter with diaphragm seal is used for boiler water level monitoring and coolant monitoring. Its high-temperature tolerance and stability make it widely applicable in power systems, ensuring safe and efficient equipment operation.

Pulp and Textile Industry - For slurries and fiber-containing liquids, the capillary level transmitter avoids the issue of tube blockages. diaphragm seal pressure transmitter is effective in the pulp and textile industries, enabling monitoring of slurry concentration and levels, which helps optimize production processes.

Order Sheet

| Item | Code | Specification |

| AT3051LT | flush diaphragm pressure transmitter/capillary level transmitter/differential level transmitter | |

| Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output | S | 4-20mA, HART Protocol, Linear output |

| Sensor Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

| Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

| Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

| Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

| Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

| Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

| Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

Production Line

single flange level transmitter Applications