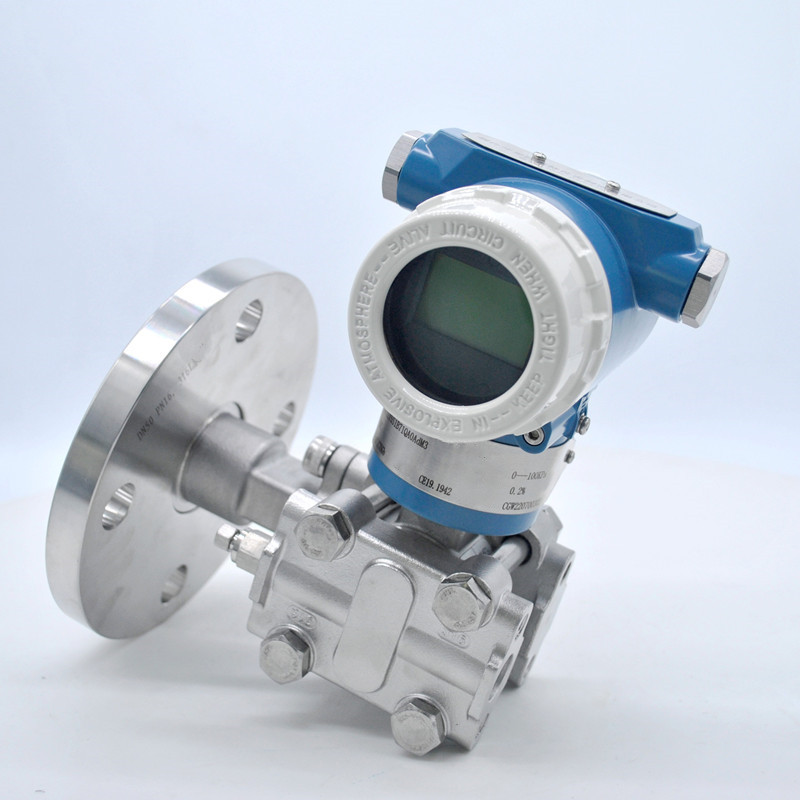

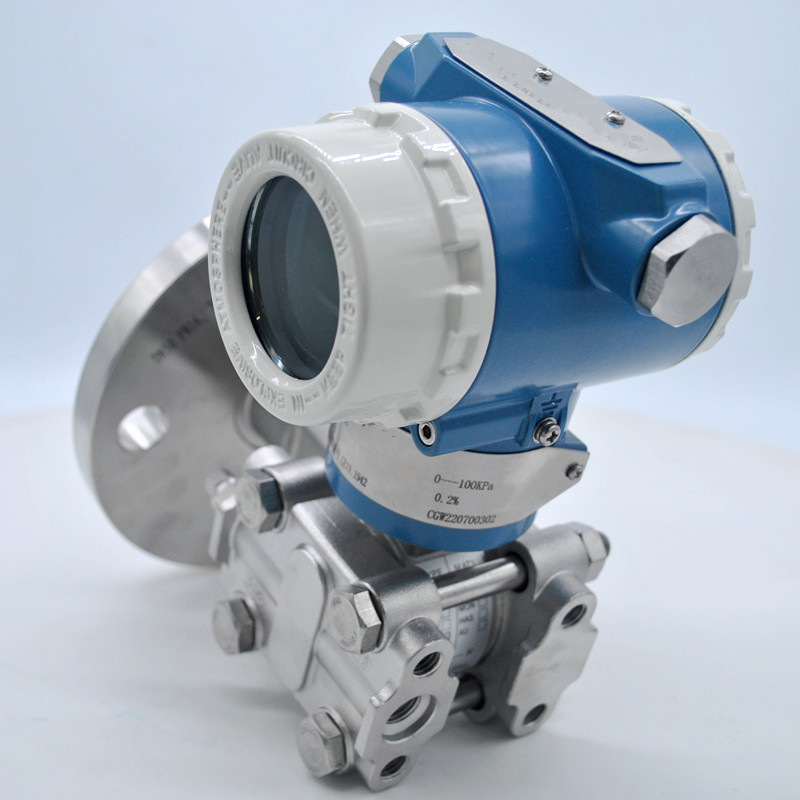

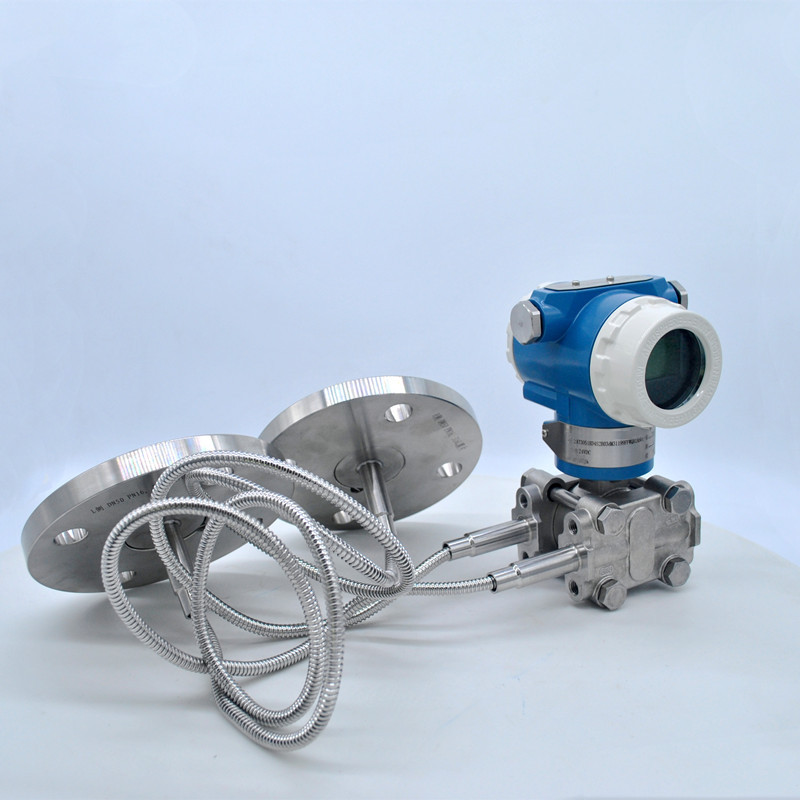

Remote Seal Flush Diaphragm Pressure Transducer

- Information

- Product Description

- Video

Brief Introduction

Brief Introduction

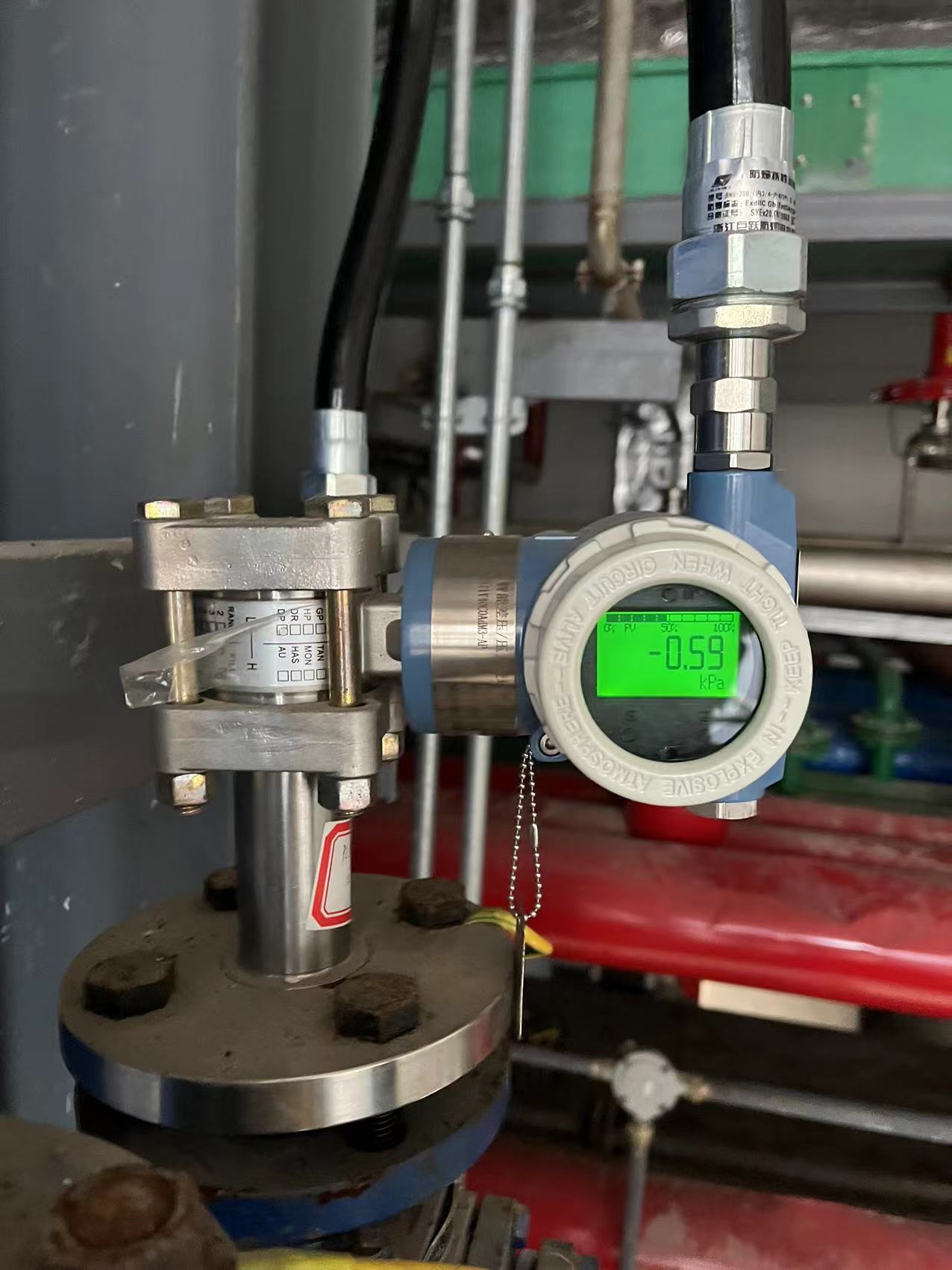

Single flange level transmitter is directly mounted on the reserved flange at the bottom of the pipeline or container, due to the isolated diaphragm directly in contact with the liquid, when the diaphragm is pressurized, it will produce a small deformation, the deformation displacement through the capillary of the silicone oil to give the sensor a signal, the sensor output signal is transmitted to the electronic module part, and is converted into a 4-20mA current signal output after processing.

Features

Liquid level in open or sealed containers.

The reference accuracy of liquid level measurement is 0.075%.

Measuring range: 6kPa~2000kPa.

2-inch, 3-inch, 4-inch flat diaphragm or extended diaphragm.

A variety of filling fluid options are available to meet various application requirements.

Damping is adjustable.

Wetted Level Materials: Stainless Steel, Hastelloy C-276 and Tantalum.

Application

The remote seal level transmitter is suitable for open vessel level pressure measurement. Can measure the level of high viscosity, easy to crystallize, easy to precipitate, and strong corrosion, and other media, according to the medium can be divided into flat flange installation and insertion cylinder installation. High viscosity, easy to crystallize, more suspended media for the insertion of cylinder level transmitter, the general media for the flat flange mounted pressure transmitter.

Order Sheet

| Item | Code | Specification |

| AT3051LT | flange mounted pressure transmitter/differential level transmitter | |

| Measurement Range | 3 | 0-4~7.5 Kpa |

| 4 | 0~37.4 Kpa | |

| 5 | 0~186.8 Kpa | |

| 6 | 0~690 Kpa | |

| 7 | 0~2068 Kpa | |

| Output | S | 4-20mA, HART Protocol, Linear output |

| Sensor Diaphragm Material / Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

| 3 | Hastelloy C Silicone Oil | |

| A | Stainless Steel 316L Fluorine oil | |

| Drain hole | B | Back of process flange or none |

| U | Process flange side upper | |

| L | Process flange side lower | |

| Wetted O-ring Material | 7 | Buna-N (NBR) |

| 6 | Viton (FKM) (Temperature ≥-20℃) | |

| 5 | Low Temperature Viton (FKM-GFLT) | |

| Cable Entry | 1 | M20*1.5 |

| Process Connection | C | 2'' ANSI 150# |

| D | 2'' ANSI 300# | |

| J | 2'' ANSI 600# | |

| E | 3'' ANSI 150# | |

| F | 3'' ANSI 300# | |

| K | 3'' ANSI 600# | |

| G | 4'' ANSI 150# | |

| H | 4'' ANSI 300# | |

| Q | DN50 PN1.6MPa/4Mpa | |

| R | DN50 PN6.4Mpa | |

| M | DN50 PN10Mpa | |

| S | DN80 PN1.6MPa/4Mpa | |

| T | DN80 PN6.4Mpa | |

| N | DN80 PN10Mpa | |

| U | DN100 PN1.6MPa/4Mpa | |

| W | DN100 PN6.4Mpa | |

| Flange Diaphragm Material | A | Stainless steel 316L |

| B | Hastelloy C | |

| C | Tantalum | |

| E | PFA coating | |

| F | F46 coating | |

| G | Gold-plated | |

| Insert Tube Length | 0 | 0 |

| 1 | 50mm | |

| 2 | 100mm | |

| 3 | 150mm | |

| Fill Fluid(High pressure side) | A | Silicone Oil |

| C | Fluorine oil | |

| Optional | d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

| i | Intrinsically safe (Exia IIC T4~T6) | |

| M3 | LCD display | |

| D1 | Stainless steel drain valve or screw (2pcs) | |

| C1 | 1/2'' NPT female waist flange (2sets) | |

| C12 | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

| C2 | M20*1.5 male thread T joint (2sets) | |

| C21 | M20*1.5 T joint -Φ14 pressure pipe (2sets) | |

| K1 | Degreasing treatment | |

Production Line

single flange level transmitter Applications

2. The diaphragm seal pressure transmitter is designed for flange mounting and offers a wide range of optional filling fluids. It ensures continuous external span and zero adjustments for precise and uninterrupted operation.