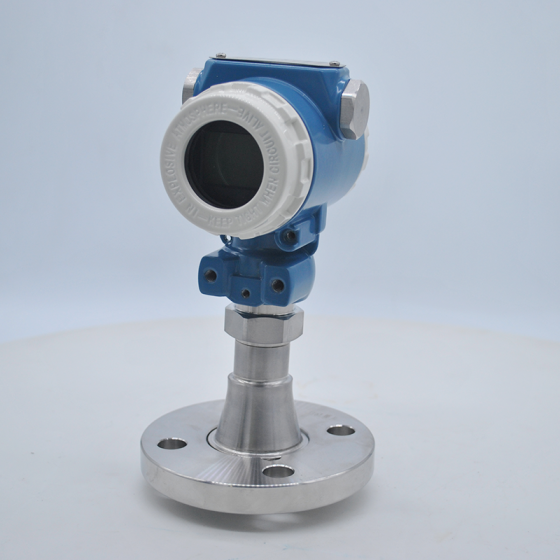

3051 Pressure Transmitter Air Pressure Sensor

- Information

- Product Description

- Video

Differential Pressure Sensor Transmitter

The digital pressure transducers are widely utilized in a variety of sectors, such as oil and gas, chemical processing, food and beverage, pharmaceuticals, and water treatment. Typically, manufacturers design and certify differential pressure transducers to meet industry standards and regulations, ensuring accuracy, reliability, and operational security.

Introduction

The gauge pressure transmitter model acts as a device for measuring and transmitting the pressure of liquids or gases in a pipeline, tank, or vessel to a control system or display unit. Through capacitive technology, the gauge pressure transmitter converts the pressure into an electrical signal, enabling its transmission to a remote location for monitoring or control objectives.

Differential pressure transducer Features

The gauge pressure transmitter is widely used for measuring differential pressure (or pressure), level , density of liquid, gas or steam. The digital pressure transducers convert the value of above into current signal output or digital protocol output.

The electronic circuit of the differential pressure sensor transmitter is extremely versatile and accurate.

The pressure transducer transmitter provides the high accuracy and range ability.

The digital gauge pressure transmitter's performance is improved by continuous monitoring of the sensor temperature and corresponding corrections.

Order Sheet

| Name | Specification Code | Description | ||

AT3051 GP AT3051 DP | YANTAI AUTO INSTRUMENT Differential Pressure Transducer Transmitter for Liquid, Gas, and Steam | |||

Measurement Range | 3 | (0.013 ~ 0.075) bar | ||

| 4 | (0.062 ~ 0.374) bar | |||

| 5 | (0.31 ~ 1.868) bar | |||

| 6 | (1.17 ~ 6.9) bar | |||

| 7 | (3.45 ~ 20.68) bar | |||

| 8 | (11.7 ~ 68.9) bar | |||

| 9 | (34.8 ~ 206.8) bar | |||

| 0 | (68.9 ~ 413.7) bar | |||

| Output Signal | E | Analog Type 4-20mA | ||

| S | 4-20mA, HART Protocol | |||

Wetted Parts Material | Flange/Joint | Exhaust/Drain Value | Diaphragm | |

| 22 | Stainless Steel | Stainless Steel | 316L Stainless Steel | |

| 23 | Hastelloy C-276 | |||

| 24 | Tantalum | |||

Mounting Bracket | B1 | Tube-type Curved Bracket (Tube ODΦ50~Φ60) | ||

| B2 | Board-type Curved Bracket | |||

| B3 | Tube-type Straight Bracket (Tube ODΦ50~Φ60) | |||

Display Header (optional) | M2 | Linear Pointer Header (0~100% scale) | ||

| M3 | Square Root Instruction Header (0~100% scale) | |||

| M4 | LCD Header (0~100% linear display) | |||

| Process Flange | D | The liquid discharge / exhaust at the back | ||

| D1 | The liquid discharge / exhaust at the side top | |||

| D2 | The liquid discharge / exhaust at the side bottom | |||

| Flange Joint | J | "D-shaped" Joint with "M20*1.5" External thread | ||

| N | Joint with 1/2-14NPT Taper Pipe Thread Waist Type | |||